When you’ve spent hours perfecting a beautiful cake, the last thing you want is for it to arrive hidden in a plain box. Custom cake boxes with window panels transform your packaging from an afterthought into a powerful marketing tool that showcases your artistry while protecting your creations.

Whether you’re a home baker scaling up or an established bakery refreshing your brand, choosing the right windowed cake boxes involves balancing aesthetics, functionality, and cost. This comprehensive guide walks you through everything you need to know about custom cake boxes with windows, from material selection to pricing considerations.

The transparent window isn’t just about looking pretty. Custom cake boxes with window serve multiple strategic purposes for your bakery business. According to recent packaging industry research, the visibility provided by windowed packaging significantly influences purchase decisions, with consumers increasingly prioritizing the ability to see products before buying.

Visibility Drives Purchase Decisions 👀 Customers can see exactly what they’re buying without opening the box, which reduces returns and increases confidence in online orders. When someone picks up a cake for a special occasion, that window lets them verify the decoration matches their expectations before leaving your shop.

Windowed Boxes Elevate Perceived Value ✨ A clear panel that frames your cake design signals quality and professionalism. It tells customers you’re proud of your work and have nothing to hide. This psychological effect often justifies premium pricing.

Marketing Assets on the Move 📸 Your beautifully decorated cake becomes a mobile advertisement when customers carry it through parking lots, offices, and party venues. The window turns every delivery into a showcase opportunity that can generate new customers through visual word-of-mouth.

Material Options: Choosing the Right Foundation 📦

The material you select determines durability, print quality, food safety, and environmental impact. Each option serves different business needs and customer expectations. Here’s what works best for cake boxes with windows.

Kraft Paperboard 🌱

Kraft paperboard offers an eco-friendly option that resonates with environmentally conscious customers. Here’s why it works:

- Natural aesthetic: The brown color provides a rustic, artisanal look perfect for organic bakeries and farmers market vendors

- Environmental benefits: Biodegradable and recyclable, appealing to eco-conscious customers

- Good strength: Sturdy enough for most cake weights

- Print quality: Accepts custom printing well, though colors appear more muted on brown base

- Brand alignment: Ideal for businesses emphasizing sustainability and natural ingredients

White Clay-Coated Paperboard ⚪

White clay-coated paperboard is the gold standard for vibrant custom printing. Consider these advantages:

- Superior print quality: Smooth white surface makes colors pop with exceptional clarity and sharpness

- Premium appearance: Clean, polished look suits upscale bakeries, wedding cakes, and luxury dessert businesses

- Moisture resistance: Coating helps prevent box weakening from condensation

- Brand flexibility: Perfect canvas for bold logos, intricate designs, and full-color artwork

- Professional presentation: Creates a high-end unboxing experience customers remember and share

This material is ideal for businesses looking to make a strong visual statement and position themselves as premium brands in the competitive bakery market.

Corrugated Cardboard 💪

For larger, heavier cakes or shipping scenarios, corrugated cardboard provides superior strength and protection:

- Maximum durability: Fluted layer absorbs impacts during transport

- Heavy-duty capacity: Essential for multi-tier wedding cakes and large orders

- Shipping friendly: Best choice for delivery services and mail orders

- Stacking strength: Handles weight without crushing when stacked

- Cost-effective protection: Prevents damage that could cost you money and reputation

While corrugated is bulkier and may feel less refined for in-store retail, it’s essential when structural integrity matters most. You can still achieve attractive custom printing on corrugated, though the textured surface may slightly affect print sharpness.

Food-Grade Considerations ✅

Regardless of which material you choose, ensure it meets food-safe standards. Your supplier should provide paperboard that’s FDA-approved for direct food contact or includes a food-safe coating. This protects your customers and shields your business from liability. At Ray Packaging, all our cake box materials comply with food safety regulations, giving you peace of mind with every order.

Window Materials: Clear Views with Smart Protection 🪟

The window itself requires careful material selection to balance visibility with structural integrity.

PET Plastic Windows

PET (polyethylene terephthalate) plastic offers crystal-clear transparency that showcases cakes beautifully while providing excellent durability:

- Crystal-clear visibility: Shows off cake details perfectly

- Durable and tear-resistant: Withstands handling during transport

- Temperature stable: Maintains clarity with temperature fluctuations

- Cost-effective: Most economical window option

- Recyclable: Can be recycled in many municipalities (requires separation from paperboard)

Biodegradable Film Windows 🌿

For eco-conscious brands, biodegradable packaging windows made from plant-based materials like PLA (polylactic acid) provide a sustainable alternative:

- Environmentally friendly: Breaks down in commercial composting facilities

- Similar appearance: Looks nearly identical to traditional plastic

- Brand alignment: Perfect for green marketing strategies

- Customer appeal: Resonates with eco-conscious consumers

- Considerations: Slightly higher cost and less heat tolerance than PET

The environmental benefits align perfectly with green branding strategies, though there’s a tradeoff in cost and temperature resistance that may matter if your cakes require refrigeration or encounter warm delivery conditions.

Window Design Considerations

Beyond material choice, think strategically about window shape, size, and placement to maximize impact:

Window Size Guidelines:

- Large centered window – Maximizes cake visibility and creates wow factor

- Smaller decorative windows – Add elegance without compromising box strength

- Multiple windows – Create unique design opportunities while maintaining structure

Creative Window Shapes:

- Circle or oval windows for classic elegance

- Heart shapes for Valentine’s Day or wedding cakes

- Custom die-cut shapes that echo your brand logo

- Geometric patterns for modern, contemporary appeal

Practical Considerations: The window should be large enough to showcase your cake’s best features while maintaining structural integrity. Too large, and the box becomes weak and difficult to stack. Too small, and you lose the visibility advantage. Work with experienced designers to find the optimal balance for your specific products.

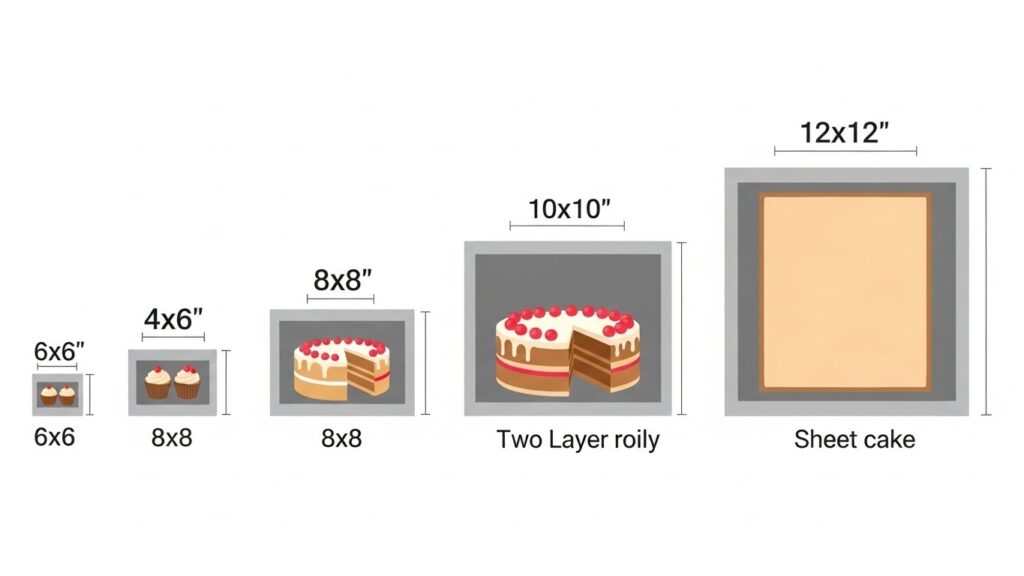

Standard Sizes and Custom Dimensions 📏

Bakery packaging with windows come in industry-standard sizes, but custom dimensions ensure a perfect fit for your specific products.

Common Standard Sizes

Most bakeries work with these standard dimensions, measured in inches:

- 6x6x3 – Perfect for personal-sized cakes, cupcake quartet boxes, and small desserts

- 8x8x4 – Fits standard round cakes up to 7 inches or square cakes (most versatile birthday cake size)

- 10x10x5 – Accommodates larger single-layer cakes (workhorse size for many bakeries)

- 12x12x6 – Suits two-layer cakes, larger sheet cakes, and substantial desserts with decorations

- 14x14x6 and larger – Handles full sheet cakes, multi-tier designs, and commercial bakery orders

Custom Sizing Benefits ✂️

While standard sizes cover most needs, custom dimensions offer significant advantages:

- Eliminates wasted space – Reduces shipping costs and material waste

- Prevents shifting – Protects delicate decorations during transport

- Signature presentation – Creates recognizable packaging customers associate with your brand

- Perfect fit every time – No more cakes sliding around in oversized boxes

- Professional appearance – Shows attention to detail and quality

Ray Packaging specializes in custom dimensions tailored to your exact specifications. Whether you need extra height for towering buttercream roses or a slim profile for flat tart presentations, we’ll engineer boxes that fit like they were made for your cakes—because they were.

Design and Branding Opportunities 🎨

Your custom cake box with window is prime real estate for brand building. Strategic design choices turn functional packaging into a memorable brand experience.

Logo Placement and Brand Colors

Your logo should appear prominently, typically on the top panel where it’s immediately visible. Using your brand’s signature colors consistently across all packaging creates instant recognition. When a customer sees your distinctive color scheme from across a room, they should immediately think of your bakery. High-quality printing ensures colors match your brand guidelines precisely, maintaining consistency with your website, signage, and other marketing materials.

Messaging and Typography

Beyond logos, consider adding taglines, social media handles, or brief messages that reinforce your brand personality. A playful bakery might include fun phrases like “Life is short, eat cake first,” while a sophisticated patisserie might opt for elegant French script. Typography choices communicate as much as the words themselves. Clean, modern fonts suggest contemporary style, while hand-drawn lettering conveys artisanal craftsmanship.

Window Framing Design

The area surrounding your window offers creative opportunities. Some bakeries use decorative borders or frames that draw attention to the window and the cake within. Others integrate the window into illustrated designs, perhaps making it appear as if the cake is sitting in a display case or on a decorative stand. These thoughtful touches elevate your packaging from merely functional to genuinely delightful.

Seasonal and Limited Edition Designs

Consider rotating designs for holidays, special events, or limited-time offerings. Valentine’s Day boxes with heart-shaped windows, Halloween designs with spooky silhouettes, or spring collections with floral patterns keep your packaging fresh and give customers reasons to order repeatedly to collect different designs. Limited edition packaging also creates urgency and exclusivity that can drive sales.

Pricing Guide: What to Expect 💰

Understanding cake box pricing helps you budget effectively and make informed decisions about order quantities and customization levels.

Factors Affecting Price

Several variables influence the final cost per box:

- Material type – Kraft paperboard (most affordable), white clay-coated (mid-range), specialty materials (premium)

- Box size – Larger dimensions require more material and cost more

- Print complexity – Single-color printing costs less than full-color designs

- Custom elements – Unique die-cuts, special finishes, and intricate designs increase setup fees

- Order quantity – Bulk orders create dramatic savings through economy of scale

General Price Ranges 💵

Here’s what to expect based on customization level:

Budget-Friendly Stock Boxes

- Price range: $0.50 – $1.50 per box

- Standard sizes with windows and minimal customization

- Bulk quantities required

- Best for: New bakeries testing packaging options

Mid-Range Custom Boxes

- Price range: $1.50 – $3.50 per box

- Two-color printing and custom dimensions

- Moderate order quantities (500-1,000 pieces)

- Best for: Established bakeries with consistent volume

Premium Fully Custom Boxes

- Price range: $3.50 – $8.00+ per box

- Elaborate designs and specialty materials

- Unique die-cut windows and special finishes

- Smaller production runs possible

- Best for: Luxury bakeries, wedding specialists, flagship products

These ranges shift based on your specific requirements, but they provide a realistic starting point for budgeting. Most successful bakeries allocate between 5% and 15% of the cake’s sale price to packaging.

Volume Discounts and Minimum Orders 📊

Bulk ordering dramatically reduces per-unit costs:

Typical Volume Discounts:

- 250 pieces – Base price

- 500 pieces – Save 15-20%

- 1,000 pieces – Save 30-40%

- 2,500 pieces – Save 40-50%

- 5,000+ pieces – Maximum savings (50%+)

Minimum Order Quantities:

- Stock boxes with minimal customization: 100-250 pieces

- Semi-custom designs: 250-500 pieces

- Fully custom with unique die-cuts: 500-1,000 pieces

- Complex designs or special materials: 1,000+ pieces

These minimums exist because creating custom printing plates, setting up die-cutting equipment, and configuring production runs involve fixed costs that must be distributed across enough units to make economic sense.

Calculating Your Investment 🧮

To evaluate whether custom boxes make financial sense for your bakery, calculate the cost per cake:

Example Calculation:

- Monthly cake sales: 100 cakes

- Average cake price: $45

- Custom box cost: $2.50 each

- Monthly packaging investment: $250

- Cost per cake: $2.50 (5.5% of sale price)

Compare this investment against the benefits:

- ✅ Premium brand perception

- ✅ Reduced damage and returns

- ✅ Increased social media sharing

- ✅ Customer loyalty and repeat business

- ✅ Higher perceived value justifying premium pricing

Most bakeries find that quality custom packaging pays for itself through increased perceived value and repeat business.

Ordering Process: From Concept to Delivery 🚚

Understanding the production timeline and ordering process helps you plan inventory and avoid rush fees.

Design and Approval Phase 🎯

Once you decide on specifications, the design process typically takes one to two weeks. You’ll work with a designer to create artwork that incorporates your branding, meets technical printing requirements, and looks stunning on the actual box.

What to Review in Proofs:

- ✅ Color accuracy matches your brand guidelines

- ✅ Text is legible and error-free

- ✅ Logo placement looks balanced

- ✅ Window positioning showcases cake optimally

- ✅ Overall aesthetic aligns with brand identity

Ray Packaging provides digital proofs showing how your design will appear on the finished product. Request revisions until everything is perfect—changes after production begins are costly or impossible.

Production Timeline ⏰

After design approval, production timelines vary based on order complexity and quantity:

- Standard orders: 2-4 weeks from approval to delivery

- Rush orders: 7-10 business days (20-50% additional fee)

- Complex custom projects: 4-6 weeks (special materials, intricate die-cuts, large quantities)

- Peak season orders: Add 1-2 weeks during wedding season, graduation, and winter holidays

Plan ahead! Production schedules fill quickly during busy seasons.

Quality Control and Samples 🔍

Before committing to a large production run, request physical samples:

What to Check in Samples:

- Print color accuracy and sharpness

- Material quality and thickness

- Box assembly ease and speed

- Window clarity and positioning

- Overall structural integrity

This small upfront investment prevents disappointment with thousands of boxes that don’t meet expectations. At Ray Packaging, we encourage sample orders and stand behind our quality with satisfaction guarantees.

Maximizing Your Investment in Custom Cake Boxes 💡

Getting the most value from custom windowed cake boxes requires strategic thinking beyond just placing an order.

Photography and Social Media 📱

Your beautiful custom boxes are content gold:

- Include social handles on boxes – Make it easy for customers to tag you

- Create a branded hashtag – Encourage customers to share unboxing photos

- Feature customer photos – Repost user-generated content (with credit)

- Run photo contests – Offer prizes for best cake box photos

- Leverage the window – Makes cakes instantly photogenic in packaging

The window makes your cakes instantly shareable, which increases organic marketing reach.

Cross-Promotion Opportunities 🎁

Use box exteriors for strategic marketing:

- QR codes – Link to online menu, reviews, or ordering page

- Discount codes – Drive repeat purchases (“Save 15% on your next order”)

- Seasonal promotions – Advertise holiday specials or new flavors

- Interior printing – Print full menu on inside lid (visible when opened)

- Event announcements – Promote classes, tastings, or special events

These subtle marketing touches keep customers thinking about your bakery long after the cake is gone.

Sustainability Messaging 🌍

If you’ve invested in eco-friendly materials, communicate it effectively. Research shows that consumers are increasingly making purchasing decisions based on sustainability, with studies indicating that approximately one in five consumers are willing to pay more for products with sustainable packaging.

How to Communicate Your Eco-Commitment:

- Add eco-friendly badges – “Made with recycled materials” or “Compostable window”

- Explain your commitment – Brief statement about environmental values

- Educate customers – Include disposal instructions for proper recycling

- Build brand loyalty – Eco-conscious consumers actively seek sustainable businesses

- Differentiate from competitors – Stand out in a crowded market

This approach not only builds goodwill but also aligns with consumer preferences, as packaging sustainability increasingly factors into purchase decisions, particularly among younger demographics.

Common Mistakes to Avoid ⚠️

Learning from others’ missteps saves you time, money, and frustration.

Choosing Price Over Quality ❌

The cheapest boxes often create the most expensive problems:

- Thin materials collapse under cake weight

- Poor printing fades or smudges quickly

- Weak windows crack during transport

- Damaged cakes hurt your reputation more than money saved

The Fix: Invest in quality packaging that protects your product and reflects your brand standards. Your cake deserves a box that matches its quality.

Neglecting Food Safety Requirements 🚫

Always verify food-safe materials and certifications:

- Ensure FDA-approved materials for food contact

- Check for food-safe coatings and inks

- Request documentation from suppliers

- Protect customers and shield your business from liability

The Fix: Reputable suppliers like Ray Packaging automatically provide compliant materials, but always ask for documentation if you’re uncertain. Never cut corners on food safety.

Ordering Without Testing Assembly 🔧

Not all box designs assemble easily:

- Complex folding slows down busy production periods

- Difficult assembly frustrates staff

- Extra time per box adds up (30 seconds × 50 cakes = 25 minutes wasted)

The Fix: Order samples and have team members assemble them to identify potential issues before ordering thousands of boxes. Efficient assembly saves labor costs and reduces frustration.

Ignoring Storage Requirements 📦

Custom boxes take up space—plan accordingly:

- Calculate storage space needed before ordering

- Crushed boxes from poor storage waste your investment

- Bulk orders save money but require adequate room

- Ensure dry, clean storage to maintain pristine condition

The Fix: Calculate storage space requirements based on box dimensions and order quantities. Don’t sacrifice box quality by cramming them into inadequate spaces.

Why Ray Packaging for Your Custom Cake Boxes with Window 🏆

Choosing the right packaging partner makes all the difference in your experience and results.

At Ray Packaging, we specialize in helping bakeries of all sizes create custom packaging that protects products and builds brands.

What Sets Us Apart:

✅ Bakery Expertise – Our design team understands the unique challenges you face ✅ Guided Process – We help optimize your design for beauty AND function ✅ Quality Guaranteed – Rigorous quality control catches issues before delivery ✅ Transparent Pricing – Clear breakdowns so you understand what you’re paying for ✅ Responsive Support – Quick answers to questions and concerns ✅ All Sizes Welcome – From first-time orders to established bakery partnerships

Most importantly, we understand that your packaging is part of your product. When a customer opens a Ray Packaging box containing your beautiful cake, they’re experiencing your brand at its best. That’s a responsibility we take seriously, and it’s why hundreds of bakeries trust us with their packaging needs.

Get Started with Your Custom Cake Boxes Today 🚀

Ready to transform your cake presentation with custom windowed boxes that showcase your artistry? The process starts with a conversation about your vision, needs, and goals.

Take the Next Step:

📞 Contact Ray Packaging today for a free consultation and quote

🎨 Discuss your vision – materials, designs, and branding goals

💰 Get transparent pricing – clear breakdown with no hidden fees

📦 Receive samples – see and feel the quality before committing

✨ Launch your new packaging – start impressing customers with every delivery

Whether you need 250 boxes or 25,000, we’ll deliver quality packaging that makes every cake delivery a brand-building opportunity.

Your cakes deserve packaging as impressive as the creations inside. Let’s build something beautiful together! 🎂✨

Frequently Asked Questions ❓

What size cake box with window do I need for an 8-inch cake?

For an 8-inch round cake, we recommend a 10x10x5 inch box to provide adequate space around the cake and prevent damage to decorations. For tall buttercream designs, consider a 10x10x6 or custom height option

Are windowed cake boxes food-safe?

Yes, when you choose FDA-approved materials from reputable suppliers like Ray Packaging. All our boxes use food-grade paperboard and certified window materials that meet safety standards for direct food contact.

Can I order small quantities for my home bakery?

Absolutely! While fully custom designs typically require minimum orders of 500-1,000 pieces, we offer semi-custom options with lower minimums (250-500 pieces). Stock boxes with basic customization can start as low as 100-250 pieces.

How long does custom printing take?

Standard custom cake boxes typically take 2-4 weeks from design approval to delivery. Rush orders (7-10 business days) are available with additional fees. Plan ahead during peak seasons like wedding season and holidays.

What’s better for the environment: PET or biodegradable windows?

Biodegradable PLA windows break down in commercial composting facilities, making them the most eco-friendly option. However, PET plastic is recyclable and performs better in temperature variations. Your choice depends on your sustainability goals and product requirements.

Can windowed boxes keep cakes fresh?

Yes, when paired with proper sealing. The box protects against physical damage and contamination, while the window allows visual inspection without opening. For maximum freshness, store cakes in a cool environment and transport promptly.

What information should I print on my cake boxes?

Essential elements include: your logo and brand name, contact information (phone, website, social media), ingredient/allergen warnings if required, handling instructions (“Keep refrigerated”), and optionally a QR code linking to your menu or ordering page.

Can I use the same box design for different cake sizes?

While possible, we recommend creating 2-3 optimized sizes for your most common products rather than one-size-fits-all. Properly fitted boxes prevent shifting, protect decorations, and reduce material waste, ultimately saving money and improving customer experience.

How should I store custom printed cake boxes?

Store boxes in a cool, dry location away from moisture and direct sunlight. Keep them flat in their original packaging to prevent crushing. Stack carefully and rotate stock to use older inventory first. Proper storage maintains print quality and structural integrity.