You’ve poured your heart into creating an incredible product. The quality is exceptional, the branding is on point, and your customers absolutely love what’s inside. But when they receive their order, the packaging is… forgettable. Generic. Maybe even damaged.

That first unboxing moment—the one that could have sparked social media shares and built brand loyalty—just became a missed opportunity.

Here’s the reality: custom gift boxes aren’t just containers. They’re your brand’s handshake, your silent salesperson, and often the first physical touchpoint your customer has with your business. Whether you’re a small artisan business shipping handmade soaps or an established brand launching a premium product line, choosing the right gift boxes can make or break your customer’s experience.

But with countless options, materials, sizes, and customization possibilities, where do you even start? Let me walk you through everything you need to know to make the perfect choice for your brand.

🎯 Understanding Your Brand’s Packaging Needs First

Before you fall in love with that gorgeous rose gold foil finish, let’s pump the brakes. The biggest mistake brands make is jumping straight into aesthetics without understanding their actual requirements.

What’s Your Product’s True Purpose?

Not all gift boxes serve the same function, and that’s okay. Are you packaging items for:

- Retail display where shelf appeal matters most?

- E-commerce shipping where durability during transit is critical?

- Special occasions like holidays, weddings, or corporate gifting?

- Subscription boxes that need to excite customers month after month?

Your product’s purpose completely changes what matters most in a gift box. A delicate glass ornament needs different protection than a leather wallet. A Valentine’s Day chocolate box has different aesthetic requirements than a corporate client appreciation gift.

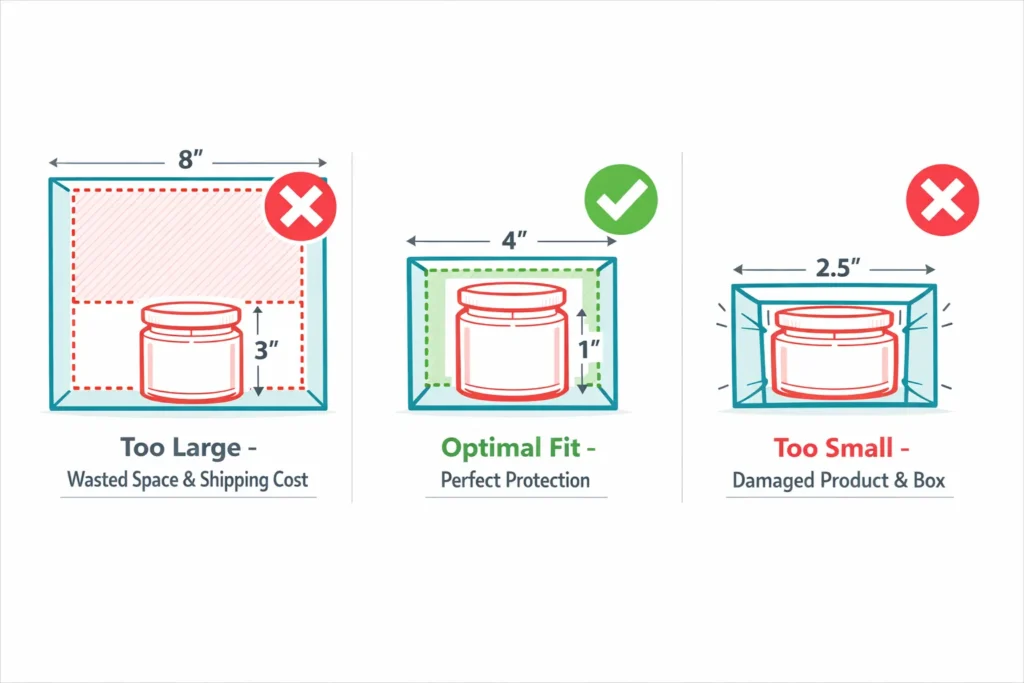

Know Your Product Dimensions (And Don’t Guess)

I can’t tell you how many brands order beautiful boxes only to discover their product doesn’t quite fit. Or worse, it rattles around inside creating a poor unboxing experience.

Measure your product carefully—length, width, and height. Then add space for any protective inserts, tissue paper, or additional items you might include. A good rule of thumb is to add ½ inch to 1 inch on each dimension for comfortable fit without excess space.

Your Customer Profile Matters More Than You Think

Who’s actually receiving these boxes? A luxury skincare brand targeting affluent women in their 40s needs entirely different packaging than a quirky subscription box for Gen Z pet owners.

Consider these factors:

- Age demographic and aesthetic preferences

- Environmental consciousness of your audience

- Price sensitivity and perceived value expectations

- Unboxing experience expectations based on competitor standards

Your customers’ values should directly influence your packaging choices. If sustainability matters to them, it needs to matter to your packaging strategy too.

📦 Material Choices That Actually Make Sense for Your Brand

Walk into any packaging supplier and you’ll hear terms like “corrugated,” “rigid,” “chipboard,” and more. Let’s cut through the confusion and talk about what actually works.

Rigid Gift Boxes: When to Invest in Premium

Rigid boxes (also called set-up boxes) are the luxury cars of the packaging world. They’re sturdy, sophisticated, and scream quality the moment someone picks them up.

Best for:

- High-end products with premium price points

- Jewelry, watches, and luxury accessories

- Technology products like headphones or smartphones

- Products where reusable packaging adds value

- Creating a “wow” factor that justifies higher prices

The catch? They’re more expensive and take up more storage space because they arrive pre-assembled. But if your product retails for $75 or more, rigid boxes often justify themselves through perceived value alone.

Folding Cartons: The Versatile Workhorse

Folding cartons ship flat and fold into shape—think of your typical cosmetics box or over-the-counter medication packaging. They’re the sweet spot between cost-effectiveness and customization.

These boxes work beautifully for:

- Mid-range products ($20-$75 retail)

- Items that need retail shelf presence

- Brands wanting extensive printing without breaking the budget

- Products that don’t require heavy-duty protection

Ray Packaging specializes in folding carton solutions that look premium without the premium price tag, making them perfect for growing brands.

Corrugated Options: More Than Just Shipping Boxes

Don’t write off corrugated boxes as purely functional. Modern printing techniques have transformed corrugated packaging into a viable branding tool.

Consider corrugated when:

- Shipping directly to consumers via e-commerce

- Products need extra cushioning during transit

- You’re working within tighter budget constraints

- Environmental sustainability is a priority (highly recyclable)

- Weight restrictions make lighter materials necessary

The key is choosing the right grade of corrugation. E-flute corrugated, for example, is much thinner and can be printed beautifully while still offering protection.

Sustainable Materials: Meeting Modern Expectations

Here’s a stat that should matter to every brand: according to Nielsen research, 73% of global consumers say they would definitely or probably change their consumption behavior to reduce environmental impact.

Sustainable options aren’t just good ethics—they’re good business:

- Recycled paperboard offering 100% post-consumer content

- FSC-certified materials from responsibly managed forests

- Biodegradable coatings replacing traditional plastic lamination

- Soy or water-based inks reducing chemical impact

Ray Packaging offers sustainable alternatives across all product lines, ensuring you don’t have to choose between environmental responsibility and beautiful packaging.

🎨 Design Elements That Transform Good Boxes into Great Experiences

Now we’re getting to the fun part—making your boxes uniquely yours. But great design isn’t about throwing every possible customization at your packaging. It’s about strategic choices that reinforce your brand.

Color Psychology in Packaging Design

Your box color isn’t just about brand guidelines—it’s triggering emotional responses before someone even opens the package.

Different colors communicate different messages:

- Black: Luxury, sophistication, exclusivity (think high-end cosmetics)

- White: Purity, simplicity, minimalism (perfect for wellness brands)

- Kraft brown: Natural, eco-friendly, artisanal (ideal for organic products)

- Pastels: Gentle, feminine, calming (popular in beauty and baby products)

- Bold colors: Energetic, playful, attention-grabbing (great for youth markets)

Consider how your color choices align with your brand personality. Mismatch here creates cognitive dissonance that weakens brand perception.

Printing Techniques Worth the Investment

Not all printing is created equal, and understanding your options helps you allocate budget where it matters most.

Offset printing delivers exceptional quality for complex designs with multiple colors. It’s economical for larger runs (typically 1,000+ units) and offers the sharpest reproduction of photographs and gradients.

Digital printing makes small batches financially viable. If you’re testing a new product line or want seasonal variations without massive inventory, digital printing is your friend. Ray Packaging’s digital capabilities mean you’re not forced into huge minimum orders.

Screen printing creates stunning bold designs and works beautifully with specialty inks like metallics. It’s perfect for minimalist designs that need maximum impact.

Special Finishes That Elevate (Without Overwhelming)

Special finishes are where boxes go from nice to memorable—but restraint is key.

Strategic finish options include:

- Spot UV coating creating glossy highlights on specific design elements

- Foil stamping (gold, silver, rose gold, holographic) for logos and accents

- Embossing or debossing adding tactile dimension

- Soft-touch coating (velvet or suede texture) that feels luxurious

- Matte lamination for modern, sophisticated appeal

Pro tip: Choose one or two special finishes rather than using everything. A debossed logo with spot UV accent often looks more expensive than a box covered in foil.

Window Cutouts: Showing Without Telling

If your product is visually appealing, why hide it? Window cutouts with clear film inserts let customers see what they’re getting while maintaining packaging integrity.

This works especially well for:

- Food products where appearance matters

- Handmade or artisanal items with visible craft quality

- Products in attractive shapes or colors

- Gift items where the recipient can peek before opening

Just ensure the window placement doesn’t compromise structural integrity or protection during shipping.

📏 Size, Structure, and Functional Considerations

Aesthetics grab attention, but functionality keeps customers coming back. Let’s talk about the practical elements that many brands overlook until they have a problem.

The True Cost of Oversized Packaging

Bigger isn’t better—it’s just more expensive. Every extra inch in your box dimensions costs you in multiple ways:

- Shipping costs increase with dimensional weight pricing

- Storage expenses eat into margins when warehousing

- Material waste frustrates environmentally conscious customers

- Poor unboxing experience when products rattle around inside

Right-sizing your packaging should be a priority from day one. Ray Packaging works with brands to optimize dimensions, ensuring snug fits that reduce costs without compromising presentation.

Closure Methods: Beyond the Basic Tuck

How your box opens and closes affects both function and perceived quality.

Common closure options include:

- Tuck closures (reverse, straight, or auto-lock) for easy assembly

- Magnetic closures creating premium opening experiences

- Ribbon ties or elastics adding decorative and functional elements

- Lock-bottom construction for heavier products needing extra support

- Two-piece construction (separate lid and base) for ultimate luxury feel

Consider how customers will interact with the closure. Will they need to open and close repeatedly? Is the unboxing moment worth a more dramatic (and expensive) closure system?

Insert Design: The Unsung Hero of Presentation

The box itself is only half the equation. What keeps your product secure and beautifully presented inside matters just as much.

Smart insert solutions include:

- Custom foam inserts for fragile or irregularly shaped items

- Molded pulp trays offering sustainable cushioning for multiple items

- Die-cut paperboard inserts creating compartments for product ranges

- Ribbon or elastic straps securing products elegantly in place

- Shredded paper or tissue for simpler, cost-effective cushioning

Your insert choice should match your brand positioning. A $200 product deserves more than crinkle paper, while a $15 item doesn’t need custom-molded foam.

💰 Budget-Smart Decision Making for Every Business Stage

Let’s address the elephant in the room: cost. Great packaging requires investment, but it shouldn’t bankrupt your business.

Understanding True Per-Unit Costs

Packaging costs aren’t just the box price. Calculate your total cost including:

- Base box manufacturing

- Design and printing fees

- Special finishes or customizations

- Inserts and protective materials

- Assembly labor (if not auto-assembling)

- Shipping to your warehouse

This total cost divided by units gives you the real per-unit expense. Many brands get sticker shock when they forget to factor in everything.

The Minimum Order Quantity Challenge

Here’s where small businesses often hit a wall. Traditional packaging suppliers demand minimums of 5,000, 10,000, or even 25,000 units.

That’s great if you’re an established brand with predictable volume. But what if you’re:

- Testing a new product line and need 500 boxes?

- Creating seasonal packaging for limited runs?

- Running a small artisan business without warehouse space?

- Wanting to update designs more frequently?

This is exactly why Ray Packaging built our business differently. We believe small businesses deserve the same quality custom gift boxes as enterprise brands—without being forced into unrealistic order quantities.

When to Invest vs. When to Save

Not every element deserves equal budget allocation. Here’s a strategic framework:

Invest more in:

- Elements customers directly interact with (texture, opening mechanism)

- Features visible in unboxing photos (exterior printing quality)

- Structural integrity for fragile products (no one shares damaged goods)

- Customizations that directly support your brand story

Save money on:

- Finishes only you will notice the difference in

- Oversized packaging creating shipping waste

- Trendy elements that’ll look dated quickly

- Interior elements hidden during the unboxing moment

🚀 Working With Packaging Suppliers: Getting It Right

You’ve figured out what you need. Now comes finding the right partner to bring your vision to life.

Questions to Ask Before Committing

Not all packaging suppliers are created equal. Vet potential partners carefully with these questions:

- What are your actual minimum order quantities (not just “low minimums”)?

- What’s the realistic timeline from design to delivery?

- Do you offer design support or just printing services?

- What happens if there’s a quality issue with my order?

- Can you provide samples before full production runs?

- How do you handle rush orders or emergency situations?

- What sustainable material options do you genuinely offer?

The answers reveal whether you’re working with a partner or just a vendor.

The Sample Process: Never Skip This Step

Seeing digital proofs on a screen is completely different from holding physical samples. Always—and I mean always—request samples before committing to large production runs.

What to evaluate in samples:

- Color accuracy compared to your brand standards

- Material quality and how it feels in hand

- Structural integrity (does it hold up to rough handling?)

- Print quality at close inspection

- Finishing details matching expectations

- Size and fit with your actual product inside

Ray Packaging provides samples at minimal cost because we know the stakes are high. A small upfront investment in samples prevents expensive mistakes later.

Communication and Turnaround Expectations

Clear communication prevents 90% of packaging disasters. Establish these expectations upfront:

- Who’s your point of contact throughout the process?

- How quickly do they respond to questions and concerns?

- What’s included in revision rounds (and what costs extra)?

- When will you receive proofs for approval?

- What’s the standard production timeline for your order?

- How do they handle shipping and logistics coordination?

If a supplier is slow or unclear during the quoting process, imagine how frustrating production will be.

🌟 Making Your Final Decision With Confidence

You’ve done the research. You understand materials, costs, and design options. Now it’s time to actually decide and move forward.

Creating Your Selection Criteria Checklist

Before finalizing any packaging choice, run through this decision-making framework:

Functional Requirements: ✓ Protects product adequately during shipping/handling ✓ Size optimized for product without excess waste ✓ Easy for customers to open without frustration ✓ Meets any regulatory requirements for your product category

Brand Alignment: ✓ Visual design reflects brand personality authentically ✓ Quality level matches product price point and positioning ✓ Sustainable choices align with brand values and customer expectations ✓ Stands out appropriately in competitive landscape

Business Viability: ✓ Per-unit cost fits within budget constraints ✓ Order quantities align with inventory and cash flow realities ✓ Lead times work with product launch schedule ✓ Supplier relationship feels reliable and communicative

If any of these areas raise red flags, pause and reconsider. Rushing into the wrong packaging solution costs more than taking time to get it right.

Testing Before Full Commitment

Even with perfect samples, real-world testing provides invaluable insights. Before ordering six months of inventory:

- Ship test packages to yourself and friends in various locations

- Have people outside your team open boxes and provide feedback

- Photograph the unboxing process as customers will see it

- Test durability by intentionally rough handling

- Gauge whether products fit properly with all intended inserts

This small-scale testing phase catches issues sample approval might miss.

Timing Your Order Strategically

Packaging production isn’t instant. Factor in realistic timelines:

- Initial design and revision: 1-2 weeks

- Sample production and shipping: 1-2 weeks

- Final approval and production setup: 1 week

- Full production run: 2-4 weeks depending on complexity

- Shipping to your location: 1-2 weeks

That’s potentially 6-11 weeks from starting design to having boxes in hand. Plan product launches accordingly, and communicate openly with your packaging supplier about any time constraints.

Don’t let urgency force you into compromises you’ll regret. Ray Packaging offers rush services when genuinely needed, but proper planning always yields better results.

✅ Your Action Plan Moving Forward

Choosing perfect gift boxes doesn’t have to be overwhelming. Break the process into manageable steps:

This week: Measure your products accurately and define your must-have vs. nice-to-have features.

Next week: Research 3-5 potential packaging suppliers and request quotes with your specifications.

Following week: Review samples from top contenders and make your selection.

Then: Place a test order, gather feedback, and refine before scaling up.

The brands that succeed with packaging are those who treat it as the marketing investment it truly is—not just an afterthought expense. Your gift boxes tell customers whether you care about details, whether you value their experience, and whether your product deserves the price you’re asking.

Ray Packaging exists to make exceptional custom packaging boxes accessible to businesses of every size. No astronomical minimums. No sacrificing quality for affordability. Just thoughtful solutions that make your brand shine.

Ready to transform your packaging from forgettable to Instagram-worthy? Let’s talk about bringing your vision to life.

Frequently Asked Questions

What’s the minimum order quantity for custom gift boxes?

Minimum order quantities vary dramatically by supplier and production method. Traditional printing often requires 5,000+ units, but digital printing technology has made runs as small as 100-250 boxes economically viable. Ray Packaging specializes in low-minimum solutions, allowing small businesses and new product lines to access custom packaging without massive inventory commitments.

How much do custom gift boxes typically cost per unit?

Custom gift box pricing ranges from $0.50 to $10+ per unit depending on size, material, printing complexity, and order quantity. Simple folding cartons with basic printing might start around $0.75-$1.50 each, while rigid boxes with special finishes can easily exceed $5 per unit. Remember to calculate total cost including design fees, samples, and shipping rather than just the per-box manufacturing cost.

How long does it take to produce custom gift boxes?

Standard production timelines typically run 4-8 weeks from final design approval to delivery. This includes production setup (2-3 days), manufacturing (1-2 weeks), and shipping (1-2 weeks). Complex orders with special finishes or materials may take longer. Many suppliers offer rush services for 25-50% additional cost, cutting timelines to 1-2 weeks.

Can I order different designs without meeting minimums for each?

Many modern packaging suppliers offer “gang run” printing, where multiple designs are printed together on the same sheet, then cut and assembled separately. This allows you to order, for example, 1,000 total boxes across three different seasonal designs (333 of each) rather than needing 1,000 of every single design. Ray Packaging frequently helps brands create variety without multiplying costs.

What’s the most eco-friendly gift box option?

The most sustainable packaging uses recycled, FSC-certified paperboard with soy or water-based inks and avoids plastic coatings or lamination. Corrugated cardboard is highly recyclable, and kraft paperboard is both biodegradable and renewable. However, true sustainability also means right-sizing packaging to eliminate waste and choosing durable materials that won’t be immediately discarded.