You’ve finally done it. Your product is ready, your brand identity is locked in, and you’re ready to start shipping orders. But then you hit a wall: packaging.

You search for “custom packaging suppliers” and get flooded with companies requiring 10,000-unit minimums, design fees that rival your entire marketing budget, and lead times that would make a sloth look speedy. Meanwhile, your competitor’s gorgeous unboxing videos are racking up views on Instagram, and you’re left wondering how they pulled it off without a Fortune 500 budget.

Here’s the truth: custom printed boxes aren’t just for big brands anymore. With the right knowledge about design principles, material choices, and cost-optimization strategies, even bootstrapped startups can create packaging that turns first-time buyers into loyal brand advocates.

📦 Why Custom Printed Boxes Matter More Than You Think

Let’s address the elephant in the room: isn’t custom packaging just an unnecessary expense?

Not even close. Custom packaging communicates professionalism, protects your product better than stock boxes, and creates a memorable first impression that influences repeat purchase rates. When a customer receives a thoughtfully designed package, they’re not just getting a product—they’re experiencing your brand values in physical form.

According to Packaging Digest’s industry research, 72% of American consumers say packaging design influences their purchasing decisions. That’s not a minor factor—it’s a major driver of consumer behavior that directly impacts your bottom line.

Think about businesses that have nailed this concept. Small-batch candle makers using elegant candle boxes create an unboxing experience that justifies premium pricing. The packaging becomes part of the product story, not just a container.

🎨 Design Fundamentals That Actually Work

Start With Your Brand Identity (Not a Blank Canvas)

The biggest mistake new businesses make? Treating packaging design as a separate project from their brand strategy.

Your box should be an extension of everything your brand already represents. Before you start sketching box designs or choosing colors, gather these elements:

- Your logo files in vector format (AI, EPS, or SVG)

- Brand color codes (CMYK for printing, not just RGB)

- Typography guidelines and font files

- Any brand patterns, textures, or graphic elements

- Your brand voice and key messaging

When these elements are already defined, your packaging design becomes exponentially easier—and more cohesive with your website, social media, and other marketing materials.

The Psychology of Color in Packaging Design

Color isn’t just aesthetic—it’s psychological. Different colors trigger specific emotional responses that can either reinforce or undermine your brand positioning.

Bold, attention-grabbing colors (reds, oranges, bright yellows) work well for impulse purchases and energetic brands. Think snack foods, toys, or fitness products.

Calm, sophisticated colors (navy, forest green, burgundy) signal premium quality and are ideal for luxury goods, organic products, or professional services.

Minimalist black and white designs communicate modern elegance and let your product be the hero. This approach works particularly well when your actual product is visually striking.

Pastel and soft colors (blush pink, mint green, lavender) appeal to gentle, nurturing brands—think skincare, baby products, or wellness items.

The key is consistency and intentionality. Your packaging colors should align with the emotional experience you want customers to have when they interact with your brand.

Typography: The Unsung Hero of Readable Packaging

Ever received a package where you couldn’t read the brand name from two feet away? That’s a typography failure, and it’s more common than you’d think.

When selecting fonts for your custom printed boxes, prioritize legibility over creativity. Your brand name should be readable at a glance, even from across a room. Here’s the hierarchy that works:

- Primary text (brand name): High contrast, bold, simple sans-serif or clean serif

- Secondary text (tagline, product name): Complementary but slightly smaller

- Tertiary text (website, social handles, legal info): Small but still legible

Never use more than two or three font families on your packaging. Visual clarity beats artistic complexity every single time.

White Space Is Your Secret Weapon

Overcrowded packaging screams “amateur hour.” White space (or negative space) gives your design room to breathe and makes your key elements stand out.

Professional packaging doesn’t need to fill every square inch with graphics or text. Strategic white space often makes packaging look more expensive and premium. Think about luxury brands—their packaging typically features generous empty space around their logo and minimal text.

When working with your designer, resist the urge to “use all that space.” Sometimes less really is more.

📐 Material Options: Matching Box Type to Your Product

Corrugated Cardboard: The Workhorse of Shipping

If you’re shipping products that need protection during transit, corrugated cardboard is your go-to material. It features a fluted layer sandwiched between two flat sheets, creating cushioning and structural strength.

Corrugated boxes come in different flute sizes:

- E-flute: Thinnest option, great for retail-ready packaging and lighter items

- B-flute: Medium thickness, balances protection with excellent printability

- C-flute: Most common for shipping, excellent cushioning for fragile items

- Double-wall: Two layers of fluting for maximum protection

For most e-commerce products, B-flute or C-flute corrugated works perfectly. The surface is smooth enough for high-quality printing while providing adequate protection during shipping.

Cardstock and Paperboard: When Presentation Takes Priority

Selling jewelry, cosmetics, or premium retail products? Cardstock or paperboard boxes deliver that upscale unboxing experience.

These materials are thinner than corrugated but offer a superior printing surface. Colors appear more vibrant, fine details stay crisp, and the overall look is more refined. They work best for:

- Products sold in physical retail stores

- Lightweight items that don’t require heavy-duty protection

- Inner boxes placed inside shipping cartons

- Subscription boxes and gift packaging

The thickness is measured in “point” (like 18pt or 24pt cardstock). Higher numbers mean sturdier boxes, but also higher costs. For most applications, 18-24pt works well.

Kraft Paper: The Eco-Friendly Choice That Customers Love

Want to appeal to environmentally conscious consumers? Kraft paper boxes have that natural, rustic aesthetic that signals sustainability and authenticity.

The beauty of kraft packaging is that it looks great even with minimal printing. A simple one-color logo on natural brown kraft creates an organic, authentic vibe. Plus, kraft material is typically made from recycled content and is fully recyclable.

Many businesses—from artisan soap makers to local bakeries—use kraft boxes with custom stamps or stickers rather than full-color printing. This cost-effective approach still delivers strong branding while maintaining that eco-conscious appeal customers appreciate.

Specialty Finishes That Elevate Your Packaging

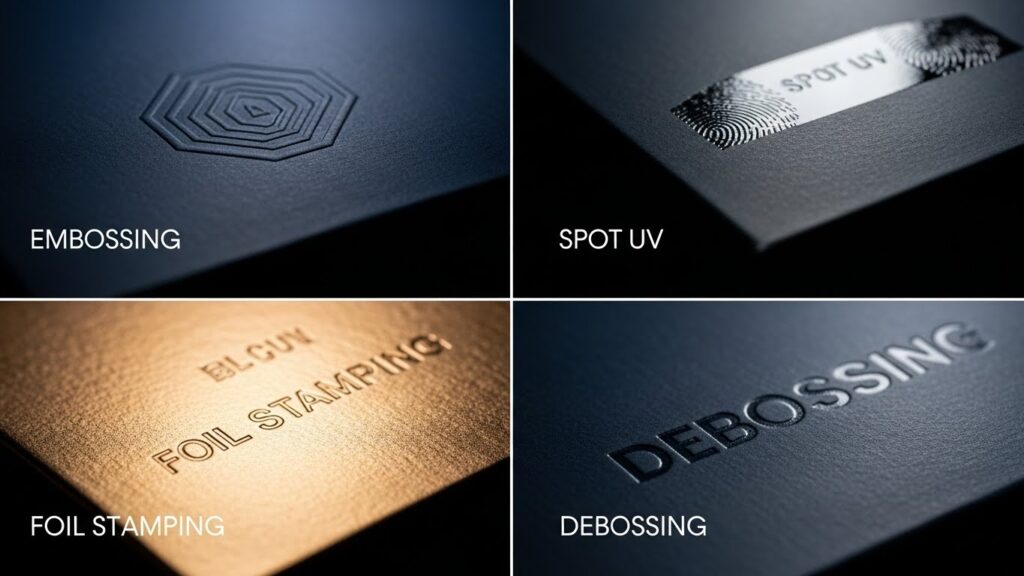

Once you’ve chosen your base material, consider these finishing options:

- Matte lamination: Smooth, non-glossy finish that feels premium

- Gloss lamination: Shiny, vibrant appearance that makes colors pop

- Spot UV: Glossy coating on specific areas for texture contrast

- Embossing/Debossing: Raised or recessed elements that add tactile interest

- Foil stamping: Metallic accents that scream luxury

These finishes increase cost, so use them strategically. Sometimes a single spot UV logo on a matte box creates more impact than covering everything in gloss.

💰 Cost-Saving Strategies That Don’t Sacrifice Quality

The Real Cost of “Standard” Minimum Orders

Let’s talk about the 800-pound gorilla in the packaging room: minimum order quantities.

Traditional packaging suppliers often require 5,000 to 10,000 units as a starting point. For a bootstrapped business just testing product-market fit, that’s an enormous financial risk. If custom boxes cost $2 each and you’re required to order 5,000 units, that’s $10,000 tied up in packaging alone.

This is where companies like Ray Packaging are changing the game. By offering low or no minimum orders, they remove the biggest barrier preventing small businesses from accessing professional custom packaging. You can order 100 boxes, test your design in the real world, gather customer feedback, and iterate—all without betting your entire marketing budget.

Size Optimization: The Hidden Cost Most People Miss

Here’s a packaging truth bomb: dimensional weight pricing means you’re charged based on box size, not just actual weight.

If your product is small but your box is huge, you’re literally paying to ship air. This is especially painful with carriers like UPS and FedEx, which calculate shipping costs using the greater of actual weight or dimensional weight.

How to optimize box sizing:

- Measure your product’s exact dimensions with padding included

- Add minimal cushioning space (usually 0.5-1 inch on each side)

- Choose the smallest box size that properly protects your product

- Consider custom die-cut inserts instead of loose fill material

- Test multiple box sizes to find the sweet spot

Working with a packaging partner that offers multiple standard sizes or custom sizing helps you find the perfect balance between protection and cost-efficiency.

Print Strategically: When Full-Color Isn’t Necessary

Full-color CMYK printing looks stunning, but it’s also the most expensive printing method. Depending on your brand aesthetic, you might not need it.

Cost-effective printing alternatives include:

- One or two-color printing: Simple designs with limited colors cost significantly less

- Kraft boxes with minimal printing: Natural brown with a black logo is both trendy and affordable

- Inside printing only: Keep the exterior simple, print your design on the interior

- Stamps and stickers: Add branding to plain boxes with custom stamps or labels

Don’t let anyone convince you that minimal printing looks cheap. Some of the most memorable unboxing experiences come from simple, well-executed designs. Brands like Glossier built cult followings with simple designs and minimal printing.

Standardize Where Possible, Customize Where It Counts

If you sell multiple products, resist the urge to create completely different box designs for each one.

Using a standardized box design across product lines dramatically reduces costs. You can differentiate products with:

- Color-coded stickers or labels

- Printed belly bands that wrap around standard boxes

- Different tissue paper colors inside the same box

- Product-specific inserts with a universal box design

This approach lets you order larger quantities of a single box design (lowering per-unit costs) while still creating variety across your product range. For instance, candle makers often use one box style with different scent labels, while food businesses benefit from versatile bakery packaging that works across multiple product lines.

Partner With Suppliers Who Understand Small Business Reality

The right packaging partner makes cost management infinitely easier. Look for suppliers who offer:

- Transparent, upfront pricing with no hidden fees

- Free or affordable design support

- Flexible order quantities that match your growth stage

- Sample boxes before committing to full orders

- Fast turnaround times that don’t require massive advance planning

Ray Packaging specializes in exactly this approach—providing enterprise-quality custom packaging with small-business-friendly terms. Their team understands that you need to test, iterate, and scale gradually rather than placing massive upfront orders.

🚀 Making Your Custom Packaging Decision

When to DIY vs. When to Hire a Designer

If you have design skills and software like Adobe Illustrator, creating your own packaging design can save money. But there’s a catch: print design requires technical knowledge beyond creating Instagram graphics.

You need to understand:

- Bleed and safe zones for printing

- CMYK color conversion (colors look different printed than on screen)

- Resolution requirements (vector files vs. raster images)

- Die lines and proper template setup

If those terms are unfamiliar, hiring a professional packaging designer is worth every penny. A poorly designed box that prints incorrectly wastes far more money than designer fees.

Many packaging suppliers, including Ray Packaging, offer design support or can connect you with experienced designers who specialize in packaging.

Getting Samples Before Committing

Never, and I mean never, order thousands of boxes without seeing a physical sample first.

Colors on your computer screen look different than printed CMYK colors. Coatings and finishes photograph differently than they feel in person. Box sizing might work on paper but feel off when you actually place your product inside.

Order sample boxes with your exact design, specifications, and finishing options. Put your actual product inside. Take photos. Show it to friends and potential customers. Make sure it’s exactly what you want before placing your full order.

This step costs a little upfront but saves you from expensive mistakes.

Scaling Your Packaging as You Grow

Your packaging strategy should evolve with your business.

Early stage (testing product-market fit): Keep it simple and affordable. Order small quantities, get customer feedback, iterate quickly.

Growth stage (consistent sales, building brand recognition): Invest in more sophisticated design, better materials, and strategic finishing options that differentiate you.

Established stage (high volume, loyal customer base): Optimize for cost efficiency at scale while maintaining the quality customers expect.

The beauty of working with flexible suppliers is that you can upgrade your packaging incrementally rather than making massive leaps that strain your budget.

✅ Final Checklist: Are You Ready to Order Custom Printed Boxes?

Before placing your order, make sure you can confidently answer yes to these questions:

- Have you finalized your brand colors in CMYK format?

- Do you have your logo in vector format (AI, EPS, or SVG)?

- Have you determined the exact box dimensions needed for your product?

- Do you know which material type best suits your product and shipping needs?

- Have you decided on printing method and any special finishes?

- Have you reviewed and approved a design proof?

- Have you ordered physical samples to test before full production?

- Do you understand lead times and have you planned accordingly?

If you answered no to any of these, take the time to sort them out. Rushing into custom packaging without preparation leads to costly mistakes.

Ray Packaging’s team can walk you through each of these steps, ensuring you make informed decisions that align with your budget, timeline, and brand goals. They’ve helped thousands of small businesses navigate their first custom packaging orders—and beyond.

Frequently Asked Questions

What’s the minimum order quantity for custom printed boxes?

Minimum orders vary widely by supplier. Traditional manufacturers often require 5,000-10,000 units, but companies like Ray Packaging offer much lower minimums or even no minimums, making custom packaging accessible for small businesses and startups just getting started.

How long does it take to receive custom printed boxes?

Typical turnaround is 2-3 weeks after design approval, though it depends on box complexity, printing method, and order quantity. Rush production may be available for an additional fee. Always plan ahead, especially before peak seasons or product launches.

Can I print photos or detailed graphics on corrugated boxes?

Yes, but results vary by printing method. Digital printing offers excellent detail for photos and gradients, while flexographic printing works better for simpler designs with solid colors. Discuss your specific design with your supplier to ensure the printing method matches your expectations.

Are custom printed boxes more expensive than plain boxes?

Custom boxes cost more per unit than plain stock boxes, but the investment pays off through brand recognition, customer experience, and reduced need for additional marketing materials. Prices have become increasingly affordable, especially with low-minimum suppliers making custom packaging accessible to businesses of all sizes.

What’s the most eco-friendly option for custom packaging?

Kraft paper boxes made from recycled content are highly sustainable and fully recyclable. Minimize plastic components, avoid excessive lamination, and use soy or water-based inks when possible. Many customers appreciate simple, minimal packaging that’s obviously eco-conscious—you don’t need elaborate designs to make an impact.