Your brand’s new product line is ready to launch. The formula is perfection, your marketing strategy is locked in, and the packaging design? Absolutely stunning. Then comes the moment of truth—you realize those gorgeous custom boxes are made from materials that’ll outlive your grandchildren in a landfill, and your environmentally conscious customers are already asking the tough questions.

The dilemma hits hard: beautiful packaging that represents your brand versus doing what’s right for the planet. For too long, businesses have felt forced to choose between visual appeal and environmental responsibility.

But here’s what’s changed: sustainable packaging has evolved far beyond the brown, rough cardboard boxes collecting dust in your mental imagery. Today’s eco-friendly materials deliver the same premium appearance, vibrant printing capabilities, and structural integrity as traditional packaging—sometimes even better.

At Ray Packaging, we’ve watched businesses completely transform their brand image while slashing their environmental impact. The breakthrough? Understanding which eco-friendly materials actually deliver on both sustainability promises and jaw-dropping visual appeal. Let’s explore everything you need to know about creating sustainable custom printed boxes that honor the planet without sacrificing an ounce of style.

🌱 Why Sustainable Packaging Isn’t Just a Trend—It’s Your Business’s Future

The packaging industry is experiencing a seismic shift, and momentum keeps building.

According to Smithers Pira research, the global sustainable packaging market is projected to reach $440 billion by 2028, driven by relentless consumer demand and tightening regulations. This isn’t superficial corporate greenwashing—real purchasing decisions hinge on environmental impact daily.

Here’s the part that should grab your attention: 73% of consumers say they would definitely or probably change their consumption habits to reduce environmental impact. That’s not a niche segment—that’s your entire customer base paying close attention.

The Real Cost of Ignoring Sustainability

Beyond shifting consumer preferences, practical business realities demand attention.

Many major retailers now enforce strict sustainability requirements for their suppliers. Planning to get your products into leading stores or popular online marketplaces? Eco-friendly packaging isn’t optional anymore—it’s the admission price. Companies pivoting now secure competitive advantages before sustainable packaging becomes universal industry standard.

The Style Misconception Holding Businesses Back

The biggest obstacle we encounter at Ray Packaging? Businesses assuming “eco-friendly” automatically translates to “visually compromised.” They imagine their premium product languishing in a dull, generic box screaming “we settled for less.”

This misconception creates real opportunity costs. Modern sustainable materials accept high-quality printing, support intricate die-cuts, and maintain structural integrity matching virgin materials perfectly. Your customers experience feel-good purchasing moments while you preserve complete brand consistency.

♻️ The Eco-Friendly Materials Revolution: Your Complete Guide

Let’s dive into specifics about materials that actually perform for custom packaging. Not every “green” option delivers equally, and understanding distinctions helps you make strategic choices.

Recycled Cardboard and Paperboard: The Reliable Foundation

Recycled cardboard remains sustainable packaging’s workhorse, but technological advances have revolutionized its capabilities.

Modern recycled paperboard matches virgin material across:

- Print quality: Advanced coating technologies ensure vibrant, razor-sharp graphics

- Structural strength: Contemporary recycling processes preserve fiber integrity beautifully

- Finish options: Gloss, matte, soft-touch, and specialty coatings all perform flawlessly

- Customization: Die-cutting, embossing, and window patching remain completely achievable

The environmental mathematics prove compelling. Using recycled cardboard slashes energy consumption by 65% compared to virgin materials and saves approximately 24 trees per ton of paper produced.

Post-Consumer vs. Post-Industrial Content: What’s the Difference?

Grasping this distinction empowers authentic customer communication.

Post-consumer recycled content originates from materials consumers have used and discarded—think cereal boxes and office paper. This represents genuine waste diversion from overflowing landfills.

Post-industrial content consists of manufacturing scraps never reaching consumers. While technically recycled, it doesn’t represent equivalent waste reduction levels.

For maximum environmental impact, seek materials with high post-consumer content percentages. Ray Packaging collaborates with suppliers offering 80-100% post-consumer recycled paperboard without sacrificing print quality.

Kraft Paper: The Natural Aesthetic Powerhouse

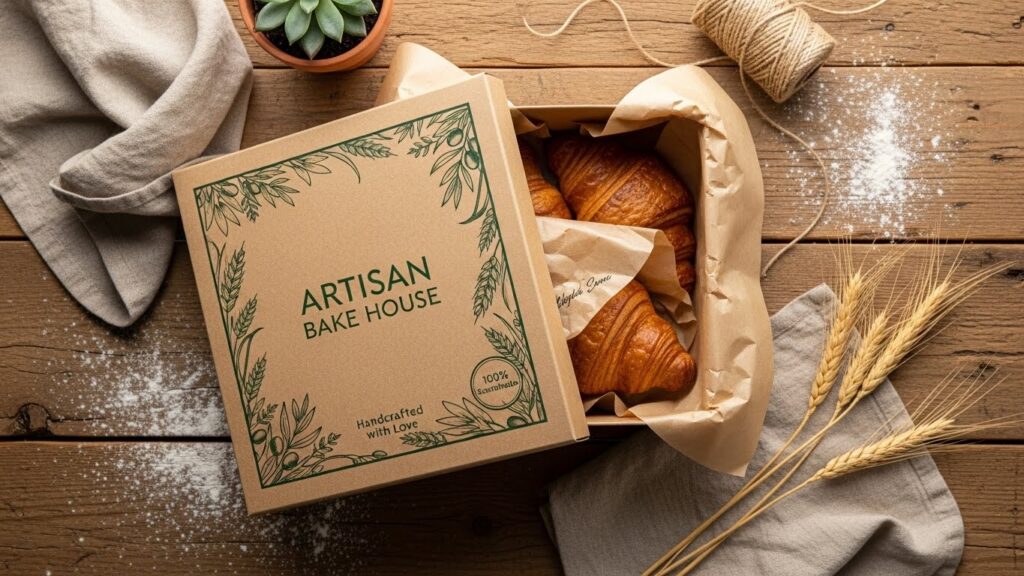

Kraft paper brings unique value to sustainable packaging: its natural brown appearance actually elevates brand perception for numerous products.

This material excels particularly for artisanal and handcrafted products where “natural” aesthetics reinforce brand values, food and beverage items where minimal processing appeals to health-conscious consumers, and bakery packaging where earthy aesthetics create premium unboxing experiences.

Kraft paper manufacturing uses fewer chemicals than bleached alternatives, and natural strength often allows reduced material usage overall. Plus, modern printing techniques create beautiful color contrast against brown backgrounds—your graphics actually pop more dramatically.

Biodegradable and Compostable Materials: The Next Frontier

This category represents sustainable packaging’s cutting edge, though requiring careful understanding.

Biodegradable materials break down naturally through microbial action over time. Materials like PLA (polylactic acid) derived from corn starch or sugarcane offer plastic-like properties without petroleum.

Compostable materials advance further, breaking down into nutrient-rich compost under specific conditions—typically within 90-180 days in commercial composting facilities.

Here’s the critical distinction: most compostable packaging requires industrial composting facilities for proper breakdown. If customers lack facility access, truly biodegradable materials might serve better.

🎨 Maintaining Premium Aesthetics with Sustainable Materials

Design possibilities with eco-friendly materials have exploded recently. Let’s explore achieving the high-end appearance your brand deserves while maintaining sustainability commitments.

Printing Techniques That Shine on Recycled Materials

Your concerns about print quality on recycled stock? Completely valid a decade ago, completely outdated today.

Modern digital and offset printing technologies deliver exceptional results on sustainable materials:

- Full-color CMYK printing produces photographic-quality images

- Pantone color matching ensures brand consistency across all packaging

- Variable data printing enables personalization for different products or customers

- UV coating adds protection and visual impact without harmful solvents

Success requires working with printers understanding how sustainable materials interact with different inks and coatings. Ray Packaging’s design team specializes in optimizing artwork specifically for eco-friendly substrates, ensuring your vision translates flawlessly.

Finishing Options That Elevate Eco-Friendly Boxes

Premium finishing techniques work beautifully with sustainable materials—you just need knowing which combinations deliver optimal results.

Soy-based and vegetable inks have replaced petroleum-based alternatives without any color vibrancy or durability loss. These inks actually produce richer, more consistent colors while remaining fully biodegradable.

Water-based coatings provide expected glossy or matte finishes while avoiding VOCs (volatile organic compounds) found in traditional coatings. Your boxes look identical to conventional packaging but break down naturally at end of life.

Embossing and debossing add tactile dimension creating memorable unboxing experiences. These techniques work especially well with kraft and recycled paperboard, where texture variations create striking visual effects.

Creating Visual Impact with Minimalist Design

Sustainable packaging pairs naturally with minimalist design aesthetics—and this works powerfully in your favor.

Clean, simple designs with strategic white space actually increase perceived brand value. Consumers associate minimalist packaging with premium, thoughtful brands. Embracing this approach simultaneously reduces ink usage (environmental win) and boosts brand perception (sales win).

Consider these design strategies:

- Use natural colors of kraft or recycled materials as palette components

- Focus on one or two bold accent colors rather than full coverage

- Let typography carry weight—beautiful fonts need fewer supporting graphics

- Incorporate natural textures and materials into your design language

📦 Structural Design: Making Eco-Friendly Boxes Work Harder

Sustainability transcends material choice—smart structural design significantly impacts environmental footprint while improving functionality.

Right-Sizing Your Packaging

One of the biggest sustainability wins comes from appropriately sized packaging. Oversized boxes waste production materials and create inefficiencies throughout entire supply chains.

Consider: smaller packages mean more units per shipping pallet, which means fewer trucks on roads, which means lower carbon emissions. Every quarter-inch trimmed from box dimensions multiplies across thousands or millions of units. This is especially important for e-commerce businesses using mailer boxes where dimensional weight pricing can significantly impact shipping costs.

Ray Packaging’s design team helps businesses optimize dimensions to fit products snugly without excess void fill, maintain structural integrity with minimum material, stack efficiently for warehousing and shipping, and meet carrier size requirements for optimal shipping rates.

Insert and Divider Solutions That Protect and Impress

Your product needs shipping protection, but traditional plastic inserts undermine sustainability efforts.

Modern alternatives include:

- Molded pulp inserts created from recycled paper that cushion products while staying fully recyclable

- Corrugated dividers custom-designed to secure products within boxes

- Shredded kraft paper as void fill doubling as rustic presentation material

- Honeycomb paper that expands filling space while providing cushioning

These solutions protect products just as effectively as plastic foam while maintaining sustainability commitments. Plus, unboxing experiences with natural materials often feel more premium than plastic alternatives.

Design for Reusability and Second Life

The most sustainable package is one not becoming waste immediately after opening.

Consider designing boxes customers want keeping and reusing. Create structures sturdy enough for long-term storage, include design elements making boxes decorative enough for display, add features like handles or closures enhancing reusability, and size boxes for standard uses like fitting on shelves or storing specific items.

When customers reuse your packaging, your brand stays visible in their homes or offices for months or years. That’s free ongoing marketing that’s also environmentally responsible.

💚 Communicating Your Sustainability Story (Without Greenwashing)

Choosing sustainable materials is half the battle—communicating commitment authentically makes real difference with customers.

Transparency Builds Trust

Today’s consumers are sophisticated about environmental claims. Vague statements like “eco-friendly” or “green” don’t cut it anymore.

Instead, be specific: state exact recycled content percentages, explain which certifications your materials hold, describe how customers should dispose of packaging, and share environmental impact differences like water saved or emissions reduced.

Ray Packaging helps businesses craft messaging that educates without overwhelming. A simple statement like “This box contains 85% post-consumer recycled content and can be recycled again in your curbside bin” gives customers actionable information.

Certifications That Actually Matter

Not all environmental certifications carry equal weight. Focus on recognized standards consumers and retailers understand.

FSC (Forest Stewardship Council) certification indicates paper comes from responsibly managed forests. This remains the gold standard for paper-based packaging. SFI (Sustainable Forestry Initiative) provides similar assurances with slightly different standards, widely accepted across North America.

Cradle to Cradle certification evaluates products across multiple sustainability categories, representing comprehensive environmental responsibility. BPI (Biodegradable Products Institute) certification verifies compostable materials actually break down as claimed—crucial for avoiding greenwashing accusations.

Making Sustainability Part of Your Brand Identity

The most effective approach integrates sustainability naturally into overall brand story rather than treating it as separate feature.

Consider how packaging choices reflect brand values. Does your company support local communities? Use regionally sourced materials. Is innovation core to your brand? Highlight cutting-edge sustainable materials. Do you emphasize quality and longevity? Explain how sustainable materials deliver durability.

When sustainability becomes inseparable from brand identity, it stops feeling like marketing claim and starts feeling like who you genuinely are as a company.

🚀 Overcoming Common Obstacles to Sustainable Packaging

Let’s address practical concerns potentially holding you back from switching to eco-friendly custom boxes.

Cost Considerations: The Real Investment Picture

Yes, sustainable materials sometimes cost more upfront. But this narrow view misses the complete financial picture.

Customer willingness to pay premium prices for sustainable products offsets material costs, shipping efficiencies from optimized packaging reduce ongoing logistics expenses, brand differentiation in crowded markets drives higher conversion rates, and regulatory compliance now versus scrambling meeting future requirements saves money long-term.

Ray Packaging works with businesses of all sizes finding sustainable solutions fitting budgets. Sometimes that means starting with recycled materials for outer packaging while gradually transitioning other elements. Progress beats perfection.

Minimum Order Quantities That Work for Small Businesses

Traditional packaging manufacturers impose high minimums making sustainable options feel impossible for smaller brands.

This is exactly why Ray Packaging focuses on serving small to medium businesses with flexible minimums. You shouldn’t need ordering 10,000 boxes accessing quality sustainable packaging.

Our approach includes low minimum orders making testing new designs affordable, digital printing capabilities reducing setup costs, design support getting sustainable packaging right the first time, and warehousing options so you can order larger quantities for cost savings without overwhelming storage.

Balancing Sustainability with Product Protection

Your packaging needs protecting products during shipping—sustainability means nothing if items arrive damaged requiring replacement shipments.

The good news? Sustainable materials can match or exceed conventional packaging in protective properties when properly engineered. The key lies in testing packaging with actual shipping conditions, using appropriate structural designs for your product weight and fragility, and selecting material thickness based on real requirements.

Working with experienced packaging designers ensures your sustainable boxes protect products just as well as any alternative while maintaining environmental benefits.

🎯 Taking Action: Your Roadmap to Sustainable Custom Printed Boxes

Ready making the switch but unsure where starting? Here’s your practical action plan.

Audit Your Current Packaging

Before changing anything, understand your starting point. What materials are you currently using? What are your biggest packaging pain points? Which elements do customers specifically mention? What’s your current cost per unit including materials, printing, and shipping?

This baseline helps you measure improvement and make informed decisions about where sustainable materials create most impact.

Define Your Sustainability Goals

Get specific about what you’re trying achieving beyond vague “eco-friendly” aspirations.

Are you prioritizing maximum recycled content regardless of cost? Compostable materials for specific customer segments? Reduced shipping costs through packaging optimization? Visual differentiation from competitors using standard packaging?

Clear goals guide material selection and help communicate values to customers. Ray Packaging’s consultation process helps clarify priorities based on specific business needs.

Start with Smart Substitutions

You don’t need overhauling everything simultaneously. Strategic substitutions create immediate impact while managing costs and complexity.

Begin with replacing virgin cardboard with recycled alternatives for existing designs, switching to soy or vegetable-based inks for current graphics, removing plastic windows or replacing them with plant-based films, and changing void fill from plastic peanuts to recycled paper or biodegradable options.

These changes require minimal design adjustments while delivering real environmental benefits you can communicate immediately.

Tell Your Story Consistently

Once you’ve made changes, communicate them across all channels. Update website product pages with sustainability information, include packaging details in marketing emails, train customer service teams discussing material choices, share behind-the-scenes content about your packaging decisions, and encourage customers sharing their experiences on social media.

Consistent storytelling transforms packaging changes from operational decision into brand differentiator attracting like-minded customers.

🤝 Why Ray Packaging Makes Sustainable Packaging Accessible

At Ray Packaging, we’ve built our entire approach around removing barriers making sustainable packaging feel impossible for small and growing businesses.

We understand you’re balancing multiple priorities—creating beautiful packaging, managing costs, protecting products, and reflecting values. That’s why we’ve eliminated traditional roadblocks.

No minimum orders means you can start with sustainable packaging immediately, whether you need 100 boxes or 10,000. Expert design support ensures your sustainable materials look exactly how you envision. Quality materials from certified suppliers give you confidence your packaging choices create real environmental impact. Fast turnaround times get your products to market quickly.

Ready creating custom printed boxes making you proud on every level? Contact Ray Packaging today discussing your specific needs and exploring sustainable solutions fitting your brand and budget perfectly.

Frequently Asked Questions:

Are sustainable custom printed boxes more expensive than traditional packaging?

Sustainable materials sometimes carry higher upfront costs, but the complete picture often shows cost parity or savings. Optimized sizing reduces shipping expenses, and many customers willingly pay premium prices for sustainable products, offsetting material costs. Additionally, as demand grows, sustainable material prices continue dropping while providing protection against future regulatory costs.

Will recycled materials affect the quality of my box printing and graphics?

Modern recycled paperboard accepts printing just as well as virgin materials when working with experienced printers. Advanced coating technologies create smooth surfaces for vibrant, sharp graphics, and you can achieve full-color CMYK printing, Pantone matching, and specialty finishes without compromise. The key lies in choosing suppliers who understand how to optimize for sustainable substrates.

How do I know if my packaging materials are truly sustainable and not greenwashing?

Look for specific certifications like FSC, SFI, or Cradle to Cradle rather than vague “eco-friendly” claims. Ask suppliers for exact recycled content percentages and sourcing information. Reputable packaging partners will provide detailed documentation about material origins and environmental impact. At Ray Packaging, we maintain transparency about all materials and certifications, giving you confidence to communicate authentically with customers.

Can sustainable packaging protect my products as well as conventional materials during shipping?

Absolutely—when properly engineered, sustainable materials match or exceed conventional packaging in protective properties. Recycled cardboard maintains excellent structural strength, and eco-friendly alternatives to plastic foam cushioning provide comparable protection. The key is working with packaging designers who understand how to optimize sustainable materials for your specific products rather than simply substituting materials without structural adjustments.

What should I do if my local recycling facilities don’t accept certain sustainable packaging materials?

Focus on widely recyclable options like FSC-certified cardboard and paper that work with standard curbside recycling programs. If using compostable materials requiring industrial facilities, include clear disposal instructions and consider your customer demographics—urban customers often have better access to commercial composting than rural customers. Providing education about disposal options helps ensure your sustainable choices create intended environmental benefits.