Every bakery owner knows the delicate balance between maintaining quality and managing costs. While you’re carefully calculating ingredient expenses and labor hours, there’s one area where many bakeries unknowingly hemorrhage profits: packaging costs. The difference between buying corrugated cake boxes wholesale and purchasing retail quantities can mean the difference between a 15% profit margin and a 30% profit margin on every cake you sell.

Consider this: if your bakery produces 200 cakes monthly and you’re spending $3 per box at retail prices when wholesale would cost $1.20, you’re losing $360 every month—that’s $4,320 annually that could go straight to your bottom line. But the financial impact goes far beyond just the price per unit. Strategic wholesale packaging decisions influence product damage rates, brand perception, customer retention, and your ability to command premium pricing.

In this comprehensive guide, we’ll unpack exactly how corrugated cake boxes wholesale purchasing transforms your bakery’s financial performance and provides you with the actionable insights you need to make smarter packaging decisions today.

Why Packaging Costs Matter More Than You Think 💰

When most bakery owners analyze their cost structure, they focus on the obvious big-ticket items: ingredients, rent, and labor. Packaging often gets lumped into “miscellaneous supplies” and escapes serious scrutiny. This oversight represents a significant missed opportunity for profit optimization.

According to research on supply chain cost management businesses that actively manage their supply chain costs can improve profit margins by 10-20% without changing their core product or pricing. Packaging typically represents 5-8% of total bakery operating costs, making it one of the most impactful areas for cost reduction.

The mathematics are straightforward but powerful. A bakery producing 500 units monthly and reducing packaging costs from $2.50 to $1.00 per unit saves $750 monthly or $9,000 annually. For a business operating on typical bakery margins of 15-20%, this represents the equivalent profit of selling an additional $45,000-$60,000 worth of product without any additional labor, ingredients, or overhead.

Beyond the direct cost savings, your packaging decisions create a ripple effect throughout your business operations. Poor packaging choices lead to increased damage rates during delivery, requiring you to remake products and eat the cost of both ingredients and labor. Inadequate packaging damages your brand reputation, making it harder to command premium pricing. Conversely, investing wisely in quality wholesale packaging creates a foundation for sustainable profitability and growth.

The key insight here is that packaging isn’t just an expense to minimize—it’s a strategic investment that influences nearly every aspect of your bakery’s financial performance. When you shift from viewing packaging as a commodity purchase to understanding it as a profit driver, your entire approach to sourcing changes.

Understanding Corrugated Cake Boxes: The Foundation of Smart Packaging 📦

Before diving into wholesale purchasing strategies, it’s essential to understand what makes corrugated packaging superior for cake transportation and how different specifications impact both cost and performance.

Corrugated cardboard consists of three layers: two flat linerboards sandwiching a wavy corrugated medium. This structure creates exceptional strength-to-weight ratio, making it ideal for protecting delicate baked goods. The air columns formed by the corrugated medium provide cushioning that absorbs shocks and impacts that would otherwise damage your cakes.

The Anatomy of Corrugated Strength

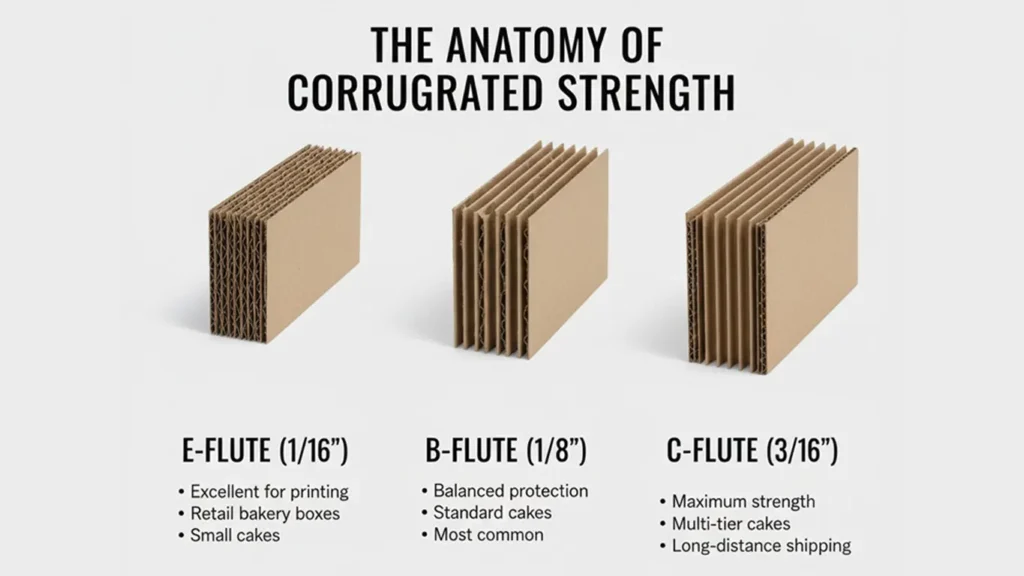

The protective capability depends on several technical specifications that directly impact both cost and performance:

E-flute (1/16 inch thickness):

- Excellent crush resistance with smooth surface ideal for high-quality printing

- Perfect for retail bakery boxes where presentation matters

- Reduces dimensional weight for shipping, lowering delivery costs

- Best for small cakes and lightweight applications

B-flute (1/8 inch thickness):

- Enhanced cushioning with strong resistance to punctures and tears

- Optimal balance between protection and cost for standard deliveries

- Provides better protection without significantly increasing material costs

- Ideal for most everyday bakery operations

C-flute (3/16 inch thickness):

- Maximum stacking strength and crush resistance

- Works best for large-tier cakes or long-distance shipping

- Costs 30-40% more due to increased material usage

- Dramatically reduces damage rates for high-value orders

The board grade, measured in GSM (grams per square meter), determines overall structural integrity. Standard corrugated cake boxes wholesale typically range from 150 GSM for lightweight applications to 300+ GSM for heavy-duty requirements.

The Real Cost Savings: Breaking Down Wholesale Pricing 💵

The most immediately obvious benefit of purchasing corrugated cake boxes wholesale is the dramatic reduction in per-unit costs. However, the true financial impact extends far beyond the simple price difference, creating multiple layers of savings that compound over time.

Direct Price Reduction Mathematics

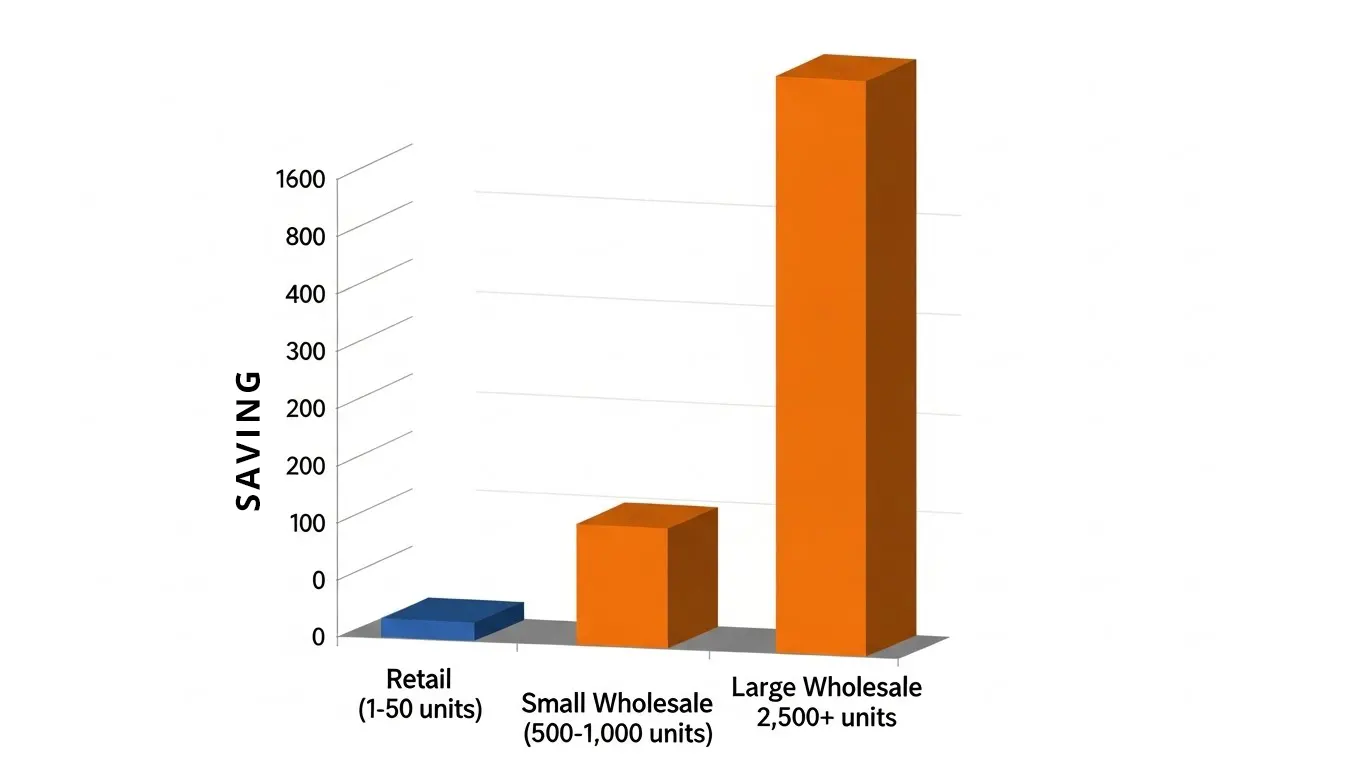

Wholesale pricing operates on volume discount principles where manufacturers can offer substantially lower prices when producing large quantities in a single run. Here’s how the pricing typically breaks down:

Retail Purchases (1-50 boxes):

- Cost: $2.50-$3.50 per unit

- Reflects inefficiency of small-batch production

- High per-order processing costs

- Limited negotiating power

Small Wholesale (500-1,000 boxes):

- Cost: $1.20-$1.80 per unit

- 40-50% savings compared to retail pricing

- Justifies dedicated production runs

- Annual savings: $2,400-$3,120 for bakeries producing 200 cakes/month

Large Wholesale (2,500-5,000 boxes):

- Cost: $0.80-$1.20 per unit

- 60-70% savings versus retail

- Requires more upfront capital and storage space

- Annual savings: $10,200-$13,500 for bakeries producing 500 units/month

Hidden Cost Reductions

Beyond the obvious per-unit savings, wholesale purchasing eliminates numerous hidden costs that drain profitability in retail buying scenarios:

Reduced Administrative Burden:

- Fewer orders mean less time on order processing and invoice management

- Reduced payment transaction fees

- Staff time redirected to revenue-generating activities

- Simplified accounting and expense tracking

Shipping Cost Optimization:

- Single wholesale delivery: $150-$200 for 1,000 boxes ($0.15-$0.20 per box)

- Ten retail orders: $400-$600 for same quantity (4x higher cost)

- Eliminates minimum shipping charges on small orders

- Avoids dimensional weight premiums

Budget Predictability:

- Lock in pricing for extended periods

- Simplified cash flow management

- Better working capital planning

- Reduced exposure to price fluctuations

How Quality Packaging Reduces Hidden Losses 🛡️

While direct packaging costs represent an obvious line item in your budget, the indirect costs of inadequate packaging often escape notice despite their significant impact on profitability. Quality corrugated cake boxes wholesale prevent losses that can easily exceed the cost of the packaging itself.

The True Cost of Product Damage

Every damaged cake represents a complete loss of ingredients, labor, and profit margin:

Direct Financial Losses:

- Ingredient costs: $15-$40 per custom cake

- Wasted labor: $75+ for 3 hours of decorator time at $25/hour

- Doubled investment when remaking for customer satisfaction

- Lost profit margin on the original sale

Customer Satisfaction Impact:

- Disappointment at significant life events (birthdays, weddings, anniversaries)

- Damaged trust and brand reputation

- Reduced likelihood of repeat business

- Negative word-of-mouth and online reviews

Industry Damage Statistics:

- Inadequate packaging: 5-8% damage rate on delivered orders

- Quality corrugated packaging: 0.5-1% damage rate

- Example savings: Reducing damage from 6% to 1% saves $900/month for 300 deliveries

- Annual prevention: $10,800 in avoided losses

Protection Creates Operational Flexibility

Quality packaging doesn’t just prevent damage; it expands your business capabilities. Sturdy corrugated cake boxes wholesale enable you to confidently accept long-distance delivery orders or shipping requests that would be too risky with inferior packaging. This geographic expansion directly increases your addressable market and revenue potential.

Reliable packaging also supports premium pricing strategies by ensuring consistent delivery of perfect products. Customers willingly pay 20-30% premiums for bakeries with reputations for flawless delivery. A bakery moving from commodity pricing of $45 per cake to premium positioning at $60 per cake sees dramatic margin improvements that dwarf packaging costs.

Choosing the Right Corrugated Specifications for Maximum Value 🎯

Optimizing your packaging investment requires matching corrugated specifications to your actual needs rather than defaulting to one-size-fits-all solutions.

Matching Packaging to Product Characteristics

Different cake types require different corrugated specifications to optimize both protection and cost-efficiency:

Small Single-Layer Cakes (6-8 inches):

- Specification: E-flute corrugated with 200 GSM

- Adequate protection without heavy-duty requirements

- Minimizes material costs and storage space

- Reduces shipping weight for additional savings

Standard Double-Layer Cakes (8-10 inches):

- Specification: B-flute corrugated at 250 GSM

- Optimal balance of protection and cost-efficiency

- Handles normal delivery conditions effectively

- Best for high-volume everyday orders

Large Multi-Tier Celebration Cakes:

- Specification: C-flute corrugated at 300+ GSM

- Maximum protection for weight and complexity

- 30-40% higher per-box cost justified by cake value

- Essential for $200-$500 premium orders

Customization Decisions That Impact Cost

When ordering corrugated cake boxes wholesale, you’ll face numerous customization options that affect both unit pricing and overall value:

Custom Printing and Branding:

- Cost addition: $0.15-$0.40 per box

- Transforms packaging into marketing asset

- Enhances perceived value and brand recognition

- Generates word-of-mouth and social media sharing

- Strong ROI for premium-positioned bakeries

Window Cutouts with Clear Film:

- Cost addition: $0.10-$0.25 per box

- Allows customers to see cake without opening

- Reduces perceived risk for online orders

- Creates Instagram-worthy unboxing experiences

- Justifies expense through improved conversion rates

Handle Cutouts or Reinforced Handles:

- Cost addition: $0.05-$0.15 per box

- Significantly improves customer transport experience

- Reduces customer-caused damage during final transport

- Almost always worth marginal cost for takeaway orders

- Small investment with high perceived value

Brand Perception: When Packaging Drives Premium Pricing 🌟

The packaging you choose communicates powerful messages about your brand positioning, quality standards, and attention to detail. Strategic investment in well-designed corrugated cake boxes wholesale creates perception advantages that translate directly into pricing power and customer loyalty.

The Psychology of Packaging Quality

Customers make unconscious quality judgments about your products based on packaging within three seconds of receiving their order. Sturdy, well-designed corrugated boxes signal professionalism, quality ingredients, and careful craftsmanship. Conversely, flimsy or generic packaging creates doubts about whether the cake inside matches expectations, even if the cake itself is perfect.

This perception gap directly impacts your ability to command premium pricing. Bakeries using custom-branded corrugated packaging with attractive design successfully charge 15-25% more than competitors using generic boxes for essentially identical products. The packaging creates a quality halo effect that influences how customers taste and evaluate the cake itself.

Social media amplification multiplies packaging’s impact on brand perception. Customers share unboxing experiences on Instagram, Facebook, and TikTok, essentially providing free advertising to their networks. Photogenic packaging with clean design, attractive branding, and thoughtful details generates significantly more social sharing than generic boxes. Each share represents dozens or hundreds of impressions from potential customers in your target demographic.

Building Brand Equity Through Consistency

Consistent use of branded corrugated cake boxes wholesale builds brand recognition that compounds over time. When customers repeatedly encounter your distinctive packaging design, they develop strong brand recall and associations. This familiarity creates preference even when customers can’t immediately remember your bakery name—they recognize “that bakery with the beautiful blue boxes.”

Brand equity created through packaging consistency also supports business expansion and new product launches. When you introduce new cake varieties or expand into related products like cupcakes or pastries, established packaging recognition transfers to these offerings and accelerates their market acceptance. The cumulative branding investment pays dividends across your entire product portfolio.

Common Mistakes That Drain Your Packaging Budget ⚠️

Even bakeries committed to wholesale purchasing often make strategic errors that diminish the financial benefits and create hidden costs. Avoiding these common pitfalls ensures you capture the full profit potential of optimized packaging strategies.

Over-Ordering and Inventory Costs

The appeal of maximum volume discounts sometimes leads bakeries to order quantities far exceeding their realistic needs. While per-unit costs decrease with volume, the total capital tied up in packaging inventory represents money unavailable for other business uses. A bakery spending $3,000 on an 18-month supply of boxes sacrifices the opportunity to invest that capital in marketing, equipment upgrades, or seasonal inventory that might generate higher returns.

Storage costs for excessive packaging inventory are easily overlooked but can negate wholesale savings. Corrugated boxes are bulky, requiring significant storage space that could otherwise generate revenue through production capacity or retail display. If you’re renting off-site storage at $200 monthly to house excess packaging, you’re spending $2,400 annually—potentially eliminating the savings from aggressive wholesale purchasing.

Inventory obsolescence presents another risk with very large orders. If you rebrand, change packaging sizes, or modify specifications, excess inventory of outdated packaging becomes waste. A thoughtful balance involves ordering enough to capture strong volume discounts (typically 6-9 months of supply) without overextending into obsolescence risk territory.

Sacrificing Quality for Marginal Price Savings

Some bakeries chase the absolute lowest per-unit cost without adequate attention to quality specifications. Choosing 150 GSM corrugated instead of 200 GSM to save $0.15 per box seems economical until damage rates increase from 1% to 4%. For a bakery producing 400 cakes monthly averaging $55 per cake, this quality downgrade costs $660 monthly in damaged products—$7,920 annually—dwarfing the $720 annual savings from cheaper boxes.

Working with unreliable suppliers based solely on price creates operational headaches that erode profitability. Late deliveries force you to make emergency retail purchases at inflated prices, negating months of wholesale savings. Quality inconsistencies require time-consuming inspections and generate customer complaints. The cheapest supplier rarely represents the best value when considering total cost of ownership.

Failing to Standardize Sizes

Many bakeries use numerous box sizes based on individual customer preferences or specific cake dimensions. This variety seems customer-friendly but creates inventory complexity and eliminates volume discounts. Ordering 200 boxes across six different sizes costs significantly more than ordering 1,200 boxes of standardized dimensions.

Standardizing on two or three core box sizes that accommodate 90% of your products captures maximum wholesale savings while maintaining flexibility:

- Use 8x8x6 inches for standard single-layer cakes

- Use 10x10x8 inches for double-layer cakes

- Use 12x12x14 inches for large celebration cakes

This simplification reduces inventory management complexity, maximizes volume discounts, and streamlines your production workflow.

Calculating Your Packaging ROI: A Practical Framework 📊

Making data-driven decisions about corrugated cake boxes wholesale requires understanding how to calculate the true return on investment.

Building Your Cost Comparison Model

Start by calculating your current total packaging costs including both obvious and hidden expenses:

Current State Assessment:

- Average monthly cake production volume

- Current price per box (retail or small quantity)

- Monthly total packaging expenditure

- Shipping costs for packaging orders

- Staff time spent ordering and managing inventory

- Estimated product damage rate with current packaging

Wholesale Research:

- Request quotes for different volume levels (500, 1000, 2500+ boxes)

- Understand minimum order quantities and delivery timeframes

- Clarify payment terms and volume commitment requirements

- Ask about damage rates other customers experience

Comprehensive Comparison:

- Direct box costs (current vs. wholesale)

- Shipping expenses (multiple small orders vs. bulk delivery)

- Inventory carrying costs (capital tied up × cost of capital percentage)

- Estimated damage reduction savings

- Time savings from reduced ordering frequency

Understanding Your Break-Even Point

Calculate how long it takes for wholesale savings to offset the increased upfront investment. If switching to wholesale requires $1,500 additional upfront capital but saves $250 monthly, your break-even occurs at six months. After that point, you’re capturing pure profit improvement that flows directly to your bottom line.

Consider seasonal patterns in your break-even analysis. Bakeries with strong seasonal peaks (wedding season, holidays) might time initial wholesale purchases to coincide with high-volume periods, ensuring rapid payback of the upfront investment.

Why Ray Packaging Is Your Strategic Partner 🤝

Transitioning to corrugated cake boxes wholesale purchasing represents a significant business decision that impacts your operations, cash flow, and product quality. Partnering with the right supplier makes the difference between successful optimization and problematic complications.

Ray Packaging specializes in serving bakeries, pastry shops, and food businesses with packaging solutions that balance quality, cost-efficiency, and reliability. Here’s what sets us apart:

Industry Specialization:

- Deep understanding of cake packaging requirements

- Food-safe materials meeting all safety regulations

- Structural integrity protecting delicate decorations

- Presentation quality reflecting your craftsmanship

Flexible Volume Options:

- Accessible minimums for boutique operations (100 cakes/month)

- Scalable solutions for established businesses (thousands of units)

- No unrealistic inventory commitments

- Substantial savings at every volume level

Quality Engineering:

- Food-grade materials with complete FDA compliance

- Crush resistance and stacking strength testing

- Vibrant printing without compromising food safety

- Specifications designed specifically for bakery applications

Expert Consultation Services:

- Analysis of your product mix and delivery methods

- Customized recommendations for cost-effective packaging

- Volume optimization based on business goals

- Guidance to avoid common wholesale mistakes

Ready to boost your bakery’s profit margins with smart packaging decisions? Contact Ray Packaging today for a customized quote on corrugated cake boxes wholesale tailored to your specific requirements. Our packaging specialists will work with you to design a solution that reduces costs, protects your products, and enhances your brand—all while improving your bottom line.

Frequently Asked Questions ❓

What is the minimum order quantity for corrugated cake boxes wholesale?

Minimum quantities typically range from 250-500 boxes for standard designs, while custom-printed boxes usually require 500-1,000 units. At Ray Packaging, we offer flexible minimums that make wholesale accessible without requiring excessive inventory commitments.

How much money can I actually save by switching to wholesale corrugated cake boxes?

Most bakeries save 40-70% on per-unit costs. For a bakery producing 300 cakes monthly, this typically translates to $2,400-$7,200 in annual savings, not including additional benefits like reduced damage rates and lower shipping costs.

Are corrugated cake boxes food-safe?

Quality corrugated boxes from reputable suppliers use food-grade materials meeting FDA regulations. Always verify food-safety certifications with your supplier and ensure they provide documentation confirming compliance.

What flute type should I choose for my cake boxes?

E-flute works well for small single-layer cakes, B-flute offers the best all-around performance for standard cakes weighing 3-8 pounds, and C-flute delivers maximum protection for large multi-tier cakes. Most bakeries find B-flute meets 70-80% of their needs.

How do I store large quantities of corrugated boxes without taking up too much space?

Corrugated boxes ship flat, with 500 boxes typically occupying just 20-30 cubic feet. Store them in a clean, dry area away from moisture, stack horizontally to prevent warping, and use vertical shelving or overhead storage racks to maximize space efficiency.

Transform your packaging from a cost center into a profit driver. Contact Ray Packaging today for a customized consultation on corrugated cake boxes wholesale solutions designed specifically for your bakery’s needs.