When you’ve spent hours creating a stunning multi-tier cake with towering decorations, the last thing you want is for your masterpiece to arrive damaged because the box wasn’t tall enough. Tall cake boxes 12x12x12 have become the go-to solution for professional bakers who refuse to compromise on presentation or protection. But what makes this specific size so popular, and why do experienced bakers consistently choose extra height packaging over standard options?

This comprehensive guide explores everything you need to know about tall cake boxes 12x12x12, from their unique advantages to material choices, pricing considerations, and real-world applications. Whether you’re a home baker scaling up or an established bakery optimizing your packaging strategy, understanding why this size dominates the industry will help you make smarter packaging decisions.

Why Height Matters in Cake Packaging 🎂

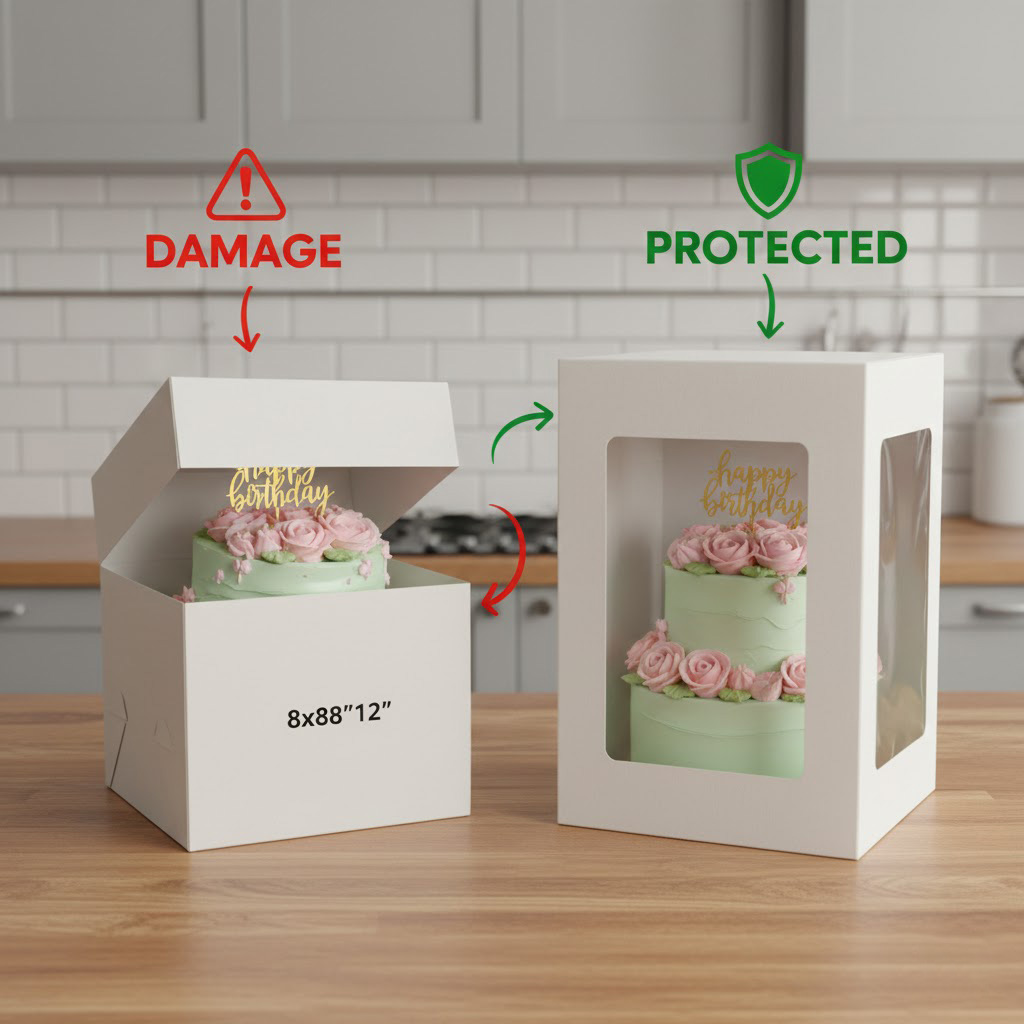

The height of your cake box directly impacts three critical factors: decoration preservation, customer satisfaction, and brand perception. Understanding these elements explains why professional bakers invest in proper vertical clearance rather than settling for standard boxes.

Decoration Protection is Non-Negotiable

Modern cake designs have evolved far beyond simple frosting. Today’s customers expect elaborate buttercream flowers, delicate fondant details, sugar sculptures, fresh floral arrangements, and dimensional toppers that add significant height to cakes. A standard 5 or 6-inch tall box simply cannot accommodate these artistic elements without forcing you to compress decorations, remove toppers, or risk damage during transport. When decorations touch the box lid, even minor movements during delivery can smudge frosting, crush flowers, or dislodge carefully placed elements.

The consequences extend beyond aesthetics. Damaged cakes lead to refund requests, negative reviews, and lost referrals. One crushed cake photograph shared on social media can undo months of reputation building. Professional bakers understand that proper packaging is not an optional expense but rather essential insurance against preventable disasters.

Customer Experience Starts with the Box

According to research on packaging psychology, consumers form immediate quality judgments based on packaging before even seeing the product inside. When a customer opens a box and sees their cake sitting with generous clearance, pristine decorations untouched, and professional presentation maintained, they perceive higher value and quality. This positive unboxing experience translates directly into satisfied customers who leave glowing reviews, refer friends, and become repeat buyers.

Conversely, opening a box to find squished decorations or frosting smeared on the lid creates immediate disappointment, regardless of how delicious the cake tastes. First impressions matter enormously in the bakery business, and your box height plays a starring role in that critical moment.

Premium Positioning Through Proper Packaging

The box you choose communicates your brand positioning. Tall boxes signal that you take your craft seriously, prioritize quality over cost-cutting, and respect the artistry involved in cake creation. This matters especially for high-ticket items like wedding cakes, custom celebration cakes, and corporate orders where customers expect premium presentation at every touchpoint.

The 12x12x12 Advantage: Perfect Proportions 📐

While tall cake boxes come in various heights, the 12x12x12 dimension has emerged as the industry sweet spot for compelling reasons that go beyond simple measurements.

Versatility Across Cake Types

The 12-inch base accommodates standard 10-inch round cakes with room for structural support, fits 10-inch square cakes comfortably, handles 8-inch cakes with generous decorative borders, and even works for certain 12-inch single-tier designs. This versatility means you can standardize on one box size for multiple products rather than stocking various dimensions, which simplifies inventory management and reduces confusion during busy production periods.

The 12-inch height specifically addresses the modern trend toward vertical cake designs. Two-tier cakes with substantial decorations, single-tier cakes with dramatic height, cakes topped with fresh flowers or elaborate toppers, and designs featuring vertical elements like tall sparkler candles or cascading sugar work all require this extra clearance. Attempting to fit these designs in 8 or 10-inch tall boxes forces compromises that diminish your creative vision.

Structural Integrity and Stability

The cube-like proportions of a 12x12x12 box provide inherent structural advantages. Equal dimensions create balanced weight distribution, the box resists crushing under stacking pressure better than tall, narrow boxes, and the proportions feel stable when carried, reducing the likelihood of tilting or tipping. This matters during transport, whether customers are carrying boxes to their cars or delivery drivers are navigating uneven surfaces.

Cost-Effectiveness at Scale

While 12x12x12 boxes cost more than standard 12x12x5 boxes, the price difference is typically modest when ordered in bulk. The investment pays dividends through reduced damage rates, fewer customer complaints and refunds, enhanced brand perception, and the ability to charge premium prices for properly presented cakes. Many bakers find that switching to appropriate tall boxes actually improves profitability by reducing waste and supporting higher pricing strategies.

What Fits in a 12x12x12 Tall Cake Box 🍰

Understanding what cakes work best in this size helps you determine if 12x12x12 boxes should become your standard or if you need multiple sizes for different products.

Ideal Cake Scenarios

Two-Tier Cakes: A 6-inch top tier on an 8 or 9-inch base tier with decorations easily fits with room to spare. This represents one of the most popular cake configurations for birthdays, anniversaries, and small celebrations. The 12-inch height accommodates the combined cake height plus decorative elements without any concern about clearance.

Tall Single-Tier Designs: Modern trends favor height over width. A single 8 or 9-inch cake with 5-6 inches of actual cake height, plus elaborate buttercream piping, sugar flowers, or architectural frosting techniques, requires substantial vertical space. The 12x12x12 box provides the necessary clearance while the square base prevents the cake from shifting.

Cakes with Dimensional Toppers: Custom cake toppers have become increasingly elaborate. Acrylic signs, LED light displays, figurines on stands, balloon arrangements, and cascading fresh flowers all add significant height. With a 12x12x12 box, you never need to ask customers to transport toppers separately or risk damage from inadequate clearance.

Wedding Cake Tiers: Individual tiers for wedding cakes being transported to venues for assembly fit perfectly. A 10-inch tier with temporary support dowels and protection fits comfortably. This size has become standard for wedding cake transportation among professional cake designers.

Specialty and Sculpted Cakes: 3D carved cakes, gravity-defying designs, and architectural cake structures often have irregular heights. The 12x12x12 box provides safety margin for these one-of-a-kind creations where slight variations in final height are difficult to predict during planning stages.

What Doesn’t Fit Well

Understanding limitations is equally important. Single-layer sheet cakes waste space in 12x12x12 boxes, small 6-inch cakes look lost and can shift during transport, and full sheet cakes require 18×24 or larger base dimensions. Having multiple box sizes available ensures you match packaging to product efficiently.

Material Options for Tall Boxes 📦

The material you choose for tall cake boxes 12x12x12 impacts durability, cost, appearance, and environmental considerations. Each option serves different business needs and customer expectations.

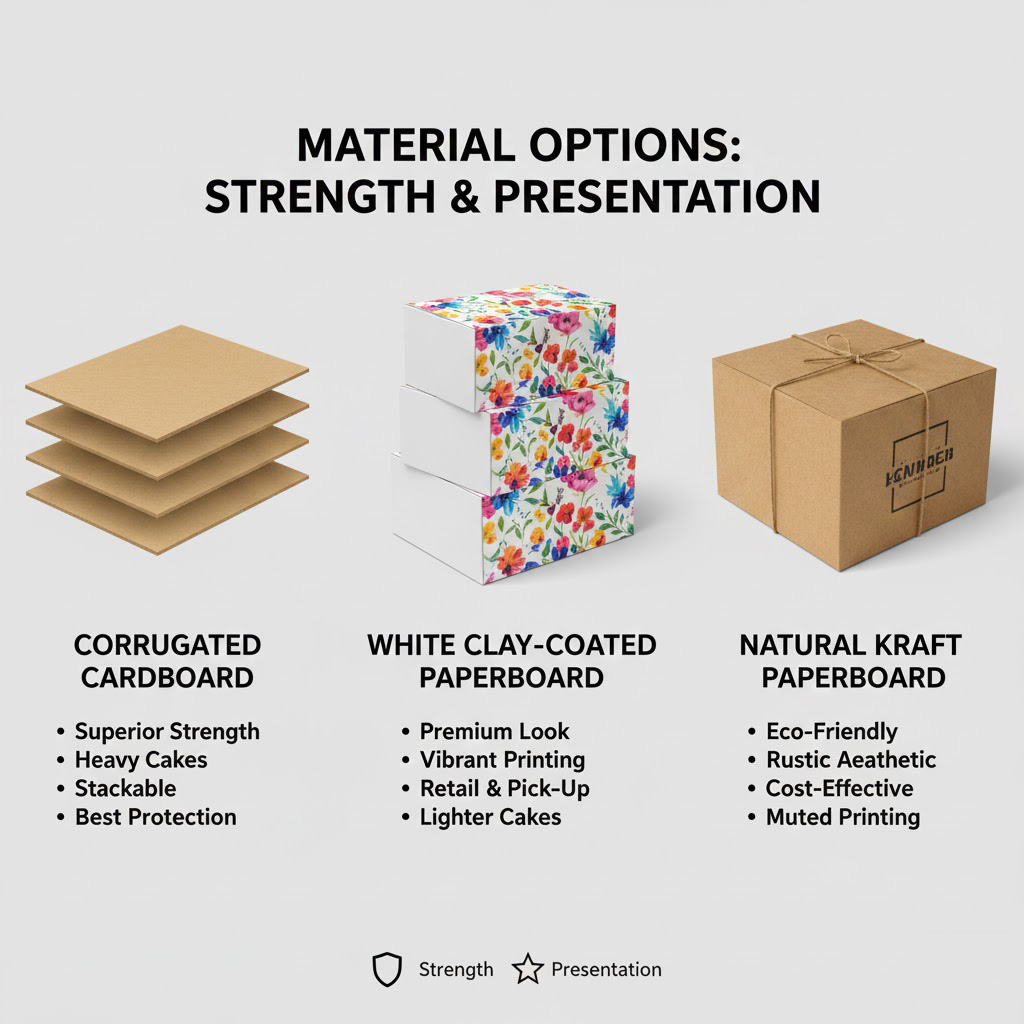

Corrugated Cardboard: The Heavy-Duty Champion

For tall boxes specifically, corrugated cardboard offers significant advantages over standard paperboard. The fluted structure between cardboard layers provides exceptional crush resistance that matters more as box height increases. Tall boxes face greater leverage forces when stacked or handled, making structural integrity crucial.

Corrugated Benefits for Tall Boxes:

- Superior strength-to-weight ratio – Handles heavy multi-tier cakes without bending

- Stack stability – Multiple tall boxes can be stacked without crushing bottom boxes

- Impact absorption – Protects cakes during bumpy deliveries and transport

- Moisture resistance – Better withstands condensation from refrigerated cakes

- Professional appearance – Available in white or kraft with excellent printing capabilities

The primary tradeoff is bulk. Corrugated boxes take up more storage space than thin paperboard, which matters when you’re storing tall boxes that already have substantial volume. However, for delivery services, wedding cakes, or any high-value orders, the protective benefits far outweigh storage considerations.

White Clay-Coated Paperboard: Premium Presentation

For retail bakery settings where cakes are hand-carried by customers and the unboxing experience matters tremendously, white clay-coated paperboard offers unmatched visual appeal. The smooth, pristine white surface creates an immediate impression of quality and cleanliness.

Ideal for:

- In-store pickup orders where customers carry boxes themselves

- Birthday and celebration cakes where presentation is paramount

- Bakeries with climate-controlled environments reducing moisture concerns

- Businesses emphasizing aesthetic branding with vibrant printed designs

- Lighter-weight single-tier cakes with elaborate decorations

The limitation comes with durability. While adequate for most applications, white paperboard doesn’t offer the same structural protection as corrugated for delivery scenarios or heavy cakes. Smart bakeries often maintain inventory of both materials, using each for appropriate situations.

Kraft Paperboard: Eco-Conscious Choice

The sustainability movement has made kraft paperboard increasingly popular, especially among bakeries marketing organic ingredients, farm-to-table concepts, or environmentally conscious branding. The natural brown appearance communicates eco-friendliness immediately and authentically.

Kraft Box Advantages:

- Biodegradable and recyclable with minimal processing

- Lower carbon footprint in manufacturing

- Rustic aesthetic that appeals to specific demographics

- Often costs less than white coated options

- Accepts stamps and natural twine decoration beautifully

The aesthetic works particularly well for farmers market vendors, organic bakeries, rustic-themed celebrations, and businesses targeting environmentally conscious consumers. However, print colors appear more muted on brown surfaces, limiting vibrant branding options.

Food-Safe Considerations for All Materials

Regardless of material choice, ensure your supplier provides food-safe certifications. Tall boxes often have cakes sitting inside for extended periods, including refrigeration and transport time. Materials must meet FDA standards for direct food contact, inks must be food-safe and migration-tested, coatings cannot transfer chemicals to cake surfaces, and adhesives used in box construction must meet safety standards.

Ray Packaging provides full documentation for all materials, ensuring compliance and giving you peace of mind that every box meets stringent safety requirements.

Window vs Non-Window: Making the Right Choice 🪟

The decision to include a window in your tall cake boxes 12x12x12 involves balancing visibility benefits against structural and cost considerations.

The Case for Windows in Tall Boxes

Visibility becomes increasingly valuable as cake complexity and price increase. When customers are paying premium prices for elaborate designs, they want assurance their cake arrived perfectly before leaving your shop or accepting delivery. A window allows verification without opening the box, which is crucial because opening tall boxes often requires breaking seals or removing lids completely, risking disturbance to the cake inside.

Windows also serve powerful marketing functions. Your beautiful cake becomes a mobile advertisement when customers carry windowed boxes through parking lots, offices, and event venues. This visual exposure generates organic marketing that fully enclosed boxes cannot provide. For bakeries building reputation and seeking word-of-mouth growth, this visibility represents significant value.

When Non-Window Boxes Make More Sense

Structural integrity increases without window cutouts. For very heavy two-tier cakes or tall sculpted designs, the uninterrupted box structure provides maximum strength. The box surface offers more space for branding, instructions, or decorative printing without working around a window frame.

Temperature considerations also matter. Cakes requiring refrigeration develop condensation that can fog windows, obscuring visibility anyway. Non-window boxes avoid this issue entirely while providing slightly better insulation properties.

Hybrid Strategy for Maximum Flexibility

Many successful bakeries maintain inventory of both window and non-window tall cake boxes 12x12x12, selecting based on specific orders. Wedding cakes often use non-window for maximum protection during transport to venues. Birthday and celebration cakes use windows for the wow factor during pickup and party arrival. High-value custom designs use windows to showcase artistry. Refrigerated cakes or long-distance deliveries use non-window for practical benefits.

This approach requires more inventory management but optimizes packaging for each situation, maximizing both protection and presentation based on actual needs.

Pricing and Value Analysis 💰

Understanding the investment required for tall cake boxes 12x12x12 helps you budget appropriately and make informed purchasing decisions.

Price Ranges and Influencing Factors

Standard White Corrugated 12x12x12 Boxes:

- Bulk orders (500-1000 units): $2.50 – $4.00 per box

- Medium orders (250-500 units): $3.50 – $5.00 per box

- Small orders (100-250 units): $4.50 – $6.50 per box

Custom Printed Boxes:

- Two-color printing: Add $0.75 – $1.50 per box

- Full-color printing: Add $1.50 – $3.00 per box

- Special finishes (foil, embossing): Add $2.00 – $4.00 per box

Window Options:

- Standard PET window: Add $0.50 – $1.00 per box

- Biodegradable window: Add $1.00 – $1.75 per box

- Custom window shapes: Add $1.50 – $2.50 per box

These prices reflect typical market rates, though specific quotes vary based on customization complexity, order quantities, and current material costs. Volume discounts become significant at higher quantities, making bulk purchasing attractive for established bakeries with consistent volume.

Calculating Cost Per Cake

To evaluate whether tall cake boxes 12x12x12 make financial sense, calculate the total packaging cost as a percentage of cake sale price. For a cake sold at $75, a $4.00 box represents approximately 5.3% of revenue. For a $150 wedding cake tier, the same $4.00 box is just 2.7% of revenue.

Compare this investment against the value delivered: complete decoration protection preventing $50-150 in refunds or remakes, premium presentation supporting higher pricing, customer satisfaction driving repeat business and referrals, and brand differentiation in competitive markets. Most bakeries find that proper tall boxes pay for themselves many times over through these tangible benefits.

Volume Planning Strategy

Smart bakeries forecast their needs quarterly and order in bulk to maximize savings. If you sell 40 tall cakes monthly, ordering 500 boxes (12-month supply) at $3.00 each costs $1,500 upfront but saves approximately $600-900 compared to ordering in smaller batches throughout the year. The storage space required for 500 boxes measuring 12x12x12 is approximately 30 cubic feet when efficiently stacked, which fits in a corner of most bakery storage areas.

Storage and Handling Considerations 📦

Tall cake boxes 12x12x12 require different storage and handling approaches compared to standard shorter boxes due to their dimensions and volume.

Efficient Storage Solutions

Flat storage is essential for maintaining box integrity. Tall boxes stored on their sides or at angles develop creases and weak points that compromise structural strength. Designate a dedicated storage area with shelving or floor space where boxes can remain flat and stacked no more than 10-12 high to prevent crushing.

The volume matters significantly. One hundred 12x12x12 boxes occupy approximately 10 cubic feet of storage space, while the same quantity of standard 12x12x5 boxes uses only about 4 cubic feet. Plan storage accordingly, especially if ordering in bulk. Some bakeries utilize vertical wall-mounted racks or overhead storage to maximize space efficiency without compromising box condition.

Assembly and Workflow Integration

Pre-creased tall boxes should fold together quickly, but the larger size requires more deliberate handling than smaller boxes. Train staff on proper assembly techniques to ensure structural integrity, particularly around corner joints and bottom flaps where stress concentrates.

Consider workflow placement. Position tall boxes near your cake decorating stations to minimize carrying distance with finished cakes. The extra height makes these boxes more awkward to transport through doorways or around tight corners, so thoughtful workspace organization prevents accidents and speeds up operations during busy periods.

Customer Handling Education

Tall boxes require different carrying techniques than standard boxes. Many customers instinctively carry boxes from the sides, which can cause tall boxes to bow in the middle. Brief customers on proper handling: support from the bottom with both hands, keep the box level during transport, avoid tilting or tipping when placing in vehicles, and position carefully in cars to prevent sliding.

Some bakeries include printed handling instructions on the box or provide verbal guidance at pickup. This small step significantly reduces damage during customer transport, which is the period when you have least control over cake safety.

Custom Branding Opportunities 🎨

Tall cake boxes 12x12x12 offer substantial surface area for branding that shorter boxes cannot match. The vertical panels provide prime real estate for building brand recognition and creating memorable customer experiences.

Maximizing Vertical Space

The tall sides of these boxes create opportunities for vertical design elements that draw the eye and stand out when boxes are carried or displayed. Consider running your logo vertically along one side panel, using the height to create visual drama. Feature customer testimonials or awards in elegant typography that reads naturally when the box is held at waist height. Include QR codes at eye level that link to ordering pages, social media, or cake galleries.

The top panel remains crucial for brand identity since it’s most visible when boxes are stacked or set on surfaces. Center your primary logo here with supporting elements around the edges, but remember the window (if included) will occupy significant top space.

Creating Unboxing Experiences

The interior of tall boxes offers hidden branding opportunities that surprise and delight customers. Print uplifting messages on the inside lid visible when opened, include care instructions with branded headers, add subtle pattern designs on interior walls, or feature a “thank you” message on the interior bottom panel visible after the cake is removed.

These thoughtful touches transform functional packaging into memorable brand experiences that customers photograph and share on social media, generating organic marketing value far beyond the modest printing cost.

Seasonal and Limited Editions

The substantial printing area on tall cake boxes 12x12x12 makes seasonal designs particularly impactful. Holiday-themed boxes for Christmas, Valentine’s Day, Easter, and other celebrations create excitement and give customers additional reasons to order. Limited edition designs for special occasions like wedding season or graduation season position your bakery as current and creative.

Rotating designs also provide natural reasons to reorder boxes throughout the year rather than committing to a single massive order, which helps manage cash flow while keeping your packaging fresh and interesting.

Common Mistakes to Avoid ⚠️

Learning from widespread errors helps you implement tall cake boxes 12x12x12 successfully from the start.

Underestimating Assembly Time

Tall boxes take longer to assemble than standard boxes, especially when staff are first learning. A standard 12x12x5 box might assemble in 15 seconds, while a 12x12x12 box often takes 25-30 seconds due to the additional material and more complex folding. During peak production times with 20-30 cakes being boxed, this time difference adds up significantly.

Solution: Practice assembly during slow periods, consider pre-assembling boxes in batches during downtime, and factor realistic time into production schedules. Some bakeries find that assembling 10-15 boxes at once during morning prep is more efficient than assembling each box individually as cakes finish.

Ignoring Base Reinforcement Needs

The bottom of tall boxes bears substantial weight, especially with multi-tier cakes or dense designs. Standard bottom flaps may not provide adequate support for heavy cakes, leading to frightening moments when bottoms sag or, worse, fail completely during transport.

Solution: Use boxes with reinforced bottoms or add corrugated cake boards that extend edge-to-edge inside the box base. This simple addition distributes weight across the entire bottom surface rather than concentrating stress on flap intersection points. For very heavy cakes, double-layer the bottom with two cake boards for absolute security.

Failing to Test With Actual Cakes

Ordering boxes based solely on measurements without physically testing them with your actual cake designs leads to unpleasant surprises. A cake that theoretically fits based on dimensions may have decorative elements that extend further than anticipated, or the box interior might have slightly less usable height than exterior measurements suggest due to material thickness.

Solution: Order samples before committing to large quantities. Actually place your typical cake designs in the sample boxes, seal them, and transport them in vehicles as customers would. This real-world testing reveals issues like insufficient clearance for specific toppers, challenges with box opening mechanisms, or visual concerns with window placement relative to cake positioning.

Overlooking Ventilation Needs

Completely sealed tall boxes can trap moisture from cakes, especially buttercream designs or cakes that were recently refrigerated. This trapped moisture condenses on box interiors and cake surfaces, potentially damaging decorations or creating an unpleasant unboxing experience with wet packaging.

Solution: Ensure boxes have small ventilation holes or slight gaps that allow air circulation without compromising structure. Many professional bakery boxes include discreet ventilation by design. If your boxes seem overly sealed, creating tiny holes in the top corners (away from cake contact areas) improves air flow without visible impact.

Why Ray Packaging for Tall Cake Boxes 🏆

Choosing the right supplier for your tall cake boxes 12x12x12 impacts everything from product quality to customer service and long-term business success.

Quality You Can Trust

Ray Packaging specializes in bakery packaging with deep understanding of the unique challenges bakers face. Our tall cake boxes 12x12x12 feature reinforced construction specifically engineered for heavy, tall cakes, food-safe materials with full compliance documentation, consistent quality across every order with rigorous inspection processes, and superior structural integrity that protects your creations during transport.

We understand that boxes aren’t mere containers but rather critical protection for hours of your skilled work. This understanding drives our commitment to excellence in every aspect of production.

Customization Expertise

Our design team has extensive experience creating custom packaging that elevates bakery brands. We guide you through material selection based on your specific needs, help optimize designs for both beauty and functionality, provide realistic timelines and transparent pricing, and deliver printed samples before full production to ensure perfect results.

Whether you need simple one-color branding or elaborate full-color designs with special finishes, we have the capabilities and expertise to bring your vision to life on tall cake boxes 12x12x12 that truly represent your brand.

Flexible Ordering and Support

We work with bakeries of all sizes, from home-based businesses to commercial operations. Our flexible minimum order quantities accommodate various business stages, volume-based pricing that rewards growth and loyalty, reliable inventory and on-time delivery, and responsive customer service that answers questions quickly.

When you partner with Ray Packaging, you gain a supplier who understands your business and genuinely wants to support your success through exceptional packaging solutions.

Get Started With Professional Tall Cake Boxes Today 🚀

Ready to elevate your cake presentation and protection with tall cake boxes 12x12x12 that professional bakers trust? The right packaging investment protects your artistry, impresses customers, and supports the premium pricing your creations deserve.

Take the Next Step:

📞 Contact Ray Packaging for a free consultation and customized quote

📦 Request samples to test with your actual cake designs before ordering

🎨 Discuss custom branding options that make your boxes uniquely yours

💰 Explore volume pricing that fits your budget and business size

✨ Start delivering cakes in packaging that matches the quality of what’s inside

Whether you need 100 boxes or 10,000, standard white or fully custom printed, we’ll deliver tall cake boxes 12x12x12 that exceed your expectations and delight your customers.

Your towering cake creations deserve packaging that rises to the occasion. Let’s build something beautiful together! 🎂✨

Frequently Asked Questions ❓

What size cake fits in a 12x12x12 box?

A 12x12x12 tall cake box accommodates 10-inch round or square cakes comfortably, 8-inch cakes with decorative borders, two-tier cakes with 6-inch top tier and 8-9 inch bottom tier, and tall single-tier designs with elaborate decorations up to 11 inches in total height. The square base provides stability while the 12-inch height protects even the most elaborate toppers and vertical decorations.

How much do tall cake boxes 12x12x12 cost?

Pricing varies based on material, customization, and order quantity. Standard white corrugated boxes typically range from $2.50-$6.50 per box depending on volume. Custom printing adds $0.75-$3.00 per box, while windows add $0.50-$1.75 per box. Bulk orders of 500+ units offer the best per-unit pricing, often 30-50% less than small quantity orders.

Should I choose window or non-window tall boxes?

Window boxes excel for retail pickup situations where customers want to verify their cake before leaving, showcase elaborate decorations during transport for marketing value, and create impressive unboxing moments. Non-window boxes offer maximum structural strength for heavy cakes, better insulation for refrigerated cakes, and more surface area for branding. Many bakeries stock both types and select based on specific order requirements.

What material is best for tall cake boxes?

Corrugated cardboard provides superior strength and protection ideal for delivery, heavy cakes, and maximum durability. White clay-coated paperboard offers premium appearance perfect for in-store pickup and vibrant custom printing. Kraft paperboard delivers eco-friendly appeal for sustainable branding. The best choice depends on your specific needs, delivery methods, and brand positioning.

How many tall boxes can I stack safely?

Corrugated tall cake boxes 12x12x12 can typically be stacked 10-12 boxes high when empty without crushing the bottom boxes. However, stacking boxes with cakes inside should be limited to 2-3 boxes maximum, and only when cakes are structurally stable and boxes are perfectly level. For transport, avoid stacking altogether and secure boxes individually to prevent shifting.